The Certifications and Accolades of AIREVERPEAK(Xingsheng):

- National Industrial Products Production License

- European Union CE Certification

- United States Market UL Certification

- ISO 9001 Quality Management System Certification

- ISO 14001 Environmental Management System Certification

- OHSAS 18000 Occupational Health and Safety Certification

- Energy Saving and Low Carbon Certification

- Mechanical and Electrical Equipment Installation Qualification II issued by the Ministry of Construction

- AAA Level Enterprise Recognition

- Jiangsu Famous Brand

- Top 100 Excellent Enterprises in China’s Refrigeration Industry

- Top Ten National Brands in China’s Refrigeration Industry

- Our Air Conditioner Terminal Products Rated as Top Ten Brands in China

Basic Introduction of HVAC Diffusers, Register & Grilles

AIREVERPEAK(XingSheng), Established in 1995, As a subsidiary of XinShengShangChi Technology Co., Ltd., is a high-tech enterprise focusing on central air-conditioning systems, including R&D, production, and installation. AIREVERPEAK (Xinsheng) benefits from the robust infrastructure and resources of the XinSheng Industrial Park. With a registered capital of 225 million RMB and a land area of 280,000 square meters, the company has substantial resources for its operations.

AIREVERPEAK(XingSheng), specializes in advanced technologies like AET (Air Energy Technology) and PET (Personal Electronics Technology), applied in efficient air conditioning systems and intelligent controls. We are dedicated to energy efficiency, environmental protection, and advancing low-carbon technologies in our products and operations. This dedication is reflected in our involvement in renewable energy projects and in integrating cutting-edge technologies into our HVAC components.

AIREVERPEAK (Xinsheng), a key player in the HVAC sector, The company is committed to energy conservation, environmental protection, and low-carbon emission reduction. The company specializes in producing premium HVAC diffusers, registers, and grilles. With approximately 30 years of experience in OEM/ODM services, the company has a strong global presence, exporting to over 150 countries.

Product Portfolio

- Variety: Over 1000 specifications in 26 categories

- Recognition: Many products are titled “high-tech products”

- Production Approach: Mass assembly line, specialization, standardization, intelligentization

- Benefits: Improved quality, efficiency, reduced cost, OEM cooperation with renowned brands

Basic types of HVAC Diffusers, Register & Grilles

Types of HVAC Diffusers, Register & Grilles

|  |  |  |

| Square Air Ceiling Diffusers | Round Air Ceiling Diffusers | HVAC Air Disc Valves | HVAC Air Vents (External Louvers) |

|  |  |  |

| HVAC Jet Nozzle Diffusers | HVAC Swirl Air Diffusers | HVAC Floor Air Registers | HVAC Plastic Diffusers & Grilles |

|  |  |  |

| HVAC Egg Crate Diffuser | HVAC Floor Grilles | HVAC Perforated Diffusers | Exhaust Air Louvers (Weatherproof Louvre) |

|  |  |  |

| HVAC Linear Bar Grilles | HVAC Linear Slot Diffusers | HVAC Deflection Grilles | HVAC Door Grilles |

|  |  |  |

| HVAC Access Panels | HVAC Dampers | Plenum Box | Neck Adaptors |

HVAC Air Disc Valves & Air Vent

|  |

| HVAC Air Disc Valves | HVAC Air Vent Caps and Louves |

HVAC Air Diffusers & Grilles

|  |

| HVAC Air Diffusers | HVAC Air Grilles |

HVAC Air Diffusers & Grilles – American & Australian

|  |

| Air Diffusers & Grilles-American series | Air Diffusers & Grilles-Australian series |

Catalog of HVAC Air Diffusers, Registers & Grilles. If want the full catalog, please CONTACT US:

- Catalog of HVAC Air Valves

- Catalog of HVAC Swirl Diffusers

- Catalog of HVAC Jet Diffusers

- Catalog of HVAC Round Air Ceiling Diffusers

- Catalog of HVAC Square Air Ceiling Diffusers

- Catalog of HVAC Linear Slot Diffusers

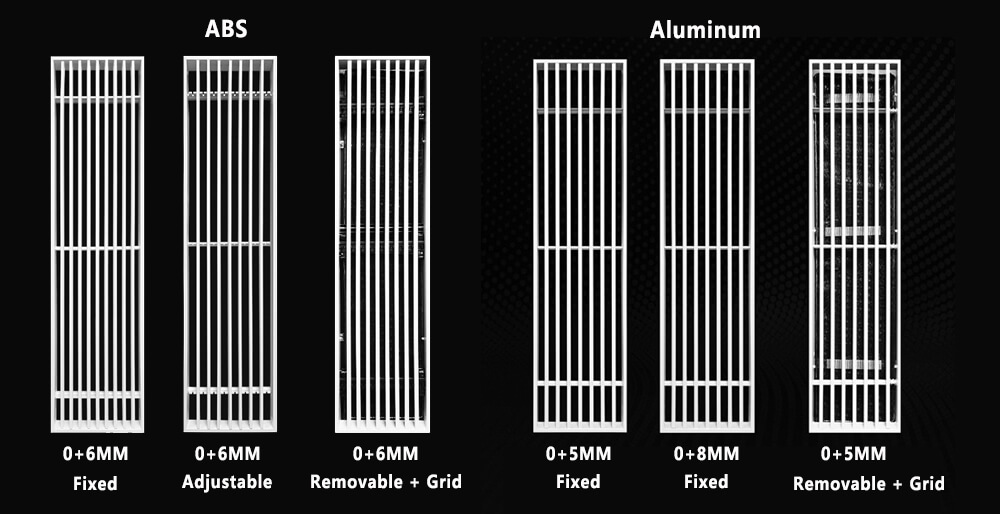

- Catalog of HVAC Linear Bar Grilles

- Catalog of HVAC Single Double Deflection Grille

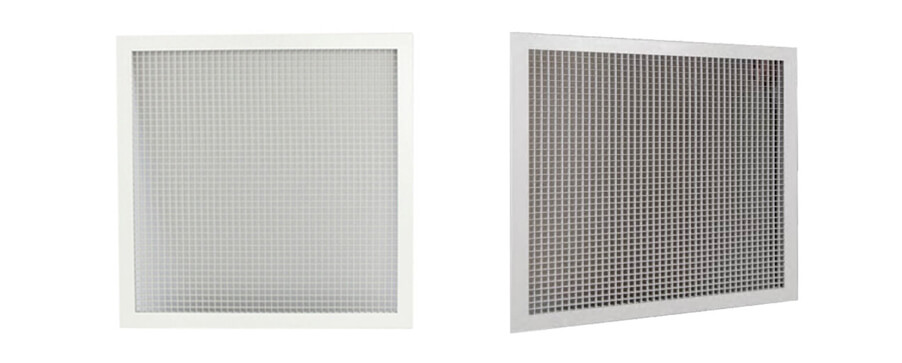

- Catalog of HVAC Egg Crate Diffusers

- Catalog of HVAC Plastic Grilles & Diffusers

- Catalog of HVAC Exhaust Air Louvre

- Catalog of HVAC Access Panel

- Catalog of HVAC Damper

- Catalog of HVAC Neck Adaptor & Plenum Box

If you want to know more, please click below:

- HVAC Linear Slot Diffusers – The Ultimate Guide

- HVAC Egg Crate Diffuser – The Ultimate Guide

- HVAC Jet Nozzle Diffuser – The Ultimate Guide

- HVAC Linear Bar Grilles – The Ultimate Guide

- HVAC Air Swirl Diffusers – The Ultimate Guide

- HVAC Round Ceiling Diffusers – The Ultimate Guide

- Round Ceiling Diffusers – The Ultimate Guide

- HVAC Return Air Grille – The Ultimate Guide

- Exhaust Air Louver – The Ultimate Guide

- HVAC Registers – The Ultimate Guide

HVAC Supply Air Diffusers – The Ultimate Guide

1. What is the HVAC Diffuser?

An HVAC diffuser is a key component in your heating, ventilation, and air conditioning system, but it has a different job compared to a damper. The diffuser is located at the end of air ducts or air outlets. HVAC diffusers make sure that the air from your system is comfortably and evenly distributed throughout the room, enhancing the overall comfort of your home.

Think of a diffuser like the nozzle on a garden hose. Just as the nozzle controls how water sprays out, the diffuser controls how air is distributed in a room. It helps spread the air evenly, so you don’t get a strong blast of air in just one spot.

Diffusers come in various shapes and sizes, designed to match different room layouts. They’re not just functional but can be decorative too, blending in with your room’s design.

2. What is a VCD Diffuser?

A VCD diffuser, which stands for Variable Circular Diffuser, is a specialized type of diffuser used in HVAC (heating, ventilation, and air conditioning) systems. It plays an important role in managing airflow in a room.

The unique feature of a VCD diffuser is its ability to adjust how much air it lets into a space. This adjustment is typically done through a mechanism that can open or close the circular blades inside the diffuser. By changing the position of these blades, the VCD diffuser can control the volume, direction, and speed of the air coming out.

This ability to adjust makes the VCD diffuser very efficient. It ensures that the right amount of air is delivered into a room based on its current needs, which could change depending on factors like room occupancy or time of day.

3. How does an HVAC Diffuser Work?

HVAC diffusers work by evenly distributing air from the ductwork into a room, controlling the direction and velocity of airflow, and aiding in air mixing for consistent temperature and air quality. Their design also considers aesthetic integration into the space and acoustic management. The effective operation of diffusers is integral to achieving a comfortable, efficient, and well-ventilated environment.

Dispersion of Air

- Even Distribution: The primary function of an HVAC diffuser is to spread air evenly across a room. It does this by diffusing the air that flows out from the HVAC system’s ductwork into the space.

Types of Airflow Patterns

- Directional Control: HVAC diffusers come in various designs that create different airflow patterns, such as linear, radial, or swirl. These patterns are crucial for directing air where it’s needed most, while avoiding drafts or hot and cold spots.

Regulation of Air Velocity

- Reducing Air Speed: As air travels through the ductwork, it moves at a high velocity. The diffuser slows down this air to a more comfortable speed as it enters the occupied space, which helps in reducing drafts and increasing comfort.

Aesthetic and Functional Design

- Blending with Decor: Besides functionality, diffusers are often designed to blend with the room’s aesthetics. They come in various shapes, sizes, and colors to match interior designs.

Air Mixing

- Temperature and Quality Consistency: By dispersing air thoroughly, diffusers aid in mixing the incoming conditioned air with the existing room air. This ensures a more consistent temperature and helps improve overall air quality.

Acoustic Management

- Noise Reduction: Advanced diffusers are designed to minimize noise as air passes through them. This is crucial in maintaining a quiet and comfortable environment, especially in spaces like offices and bedrooms.

Enhancing System Efficiency

- Optimal Use of HVAC: Properly designed and placed diffusers can enhance the overall efficiency of an HVAC system. They ensure that the air conditioning, heating, or ventilation is effectively utilized throughout the space.

4. What is HVAC Air Balancing?

HVAC air balancing is the process of optimizing an HVAC (Heating, Ventilation, and Air Conditioning) system to ensure uniform and efficient distribution of air throughout a building. This involves adjusting the system to provide the right amount of air to each room, creating a consistently comfortable environment, and improving overall system performance. The goal of HVAC air balancing is to eliminate areas that are too hot or too cold, thereby enhancing the comfort of occupants and the energy efficiency of the system.

5. What is the Difference between Grille, Register, and Diffuser in HVAC Systems?

Let’s take a look at one video for review:

In HVAC (Heating, Ventilation, and Air Conditioning) systems, the terms grille, register, and diffuser refer to different types of air distribution devices, each serving a specific function.

Grille

- Function: A grille is a cover with slats or a perforated design, typically used for air return. It covers the opening where the air is drawn back into the HVAC system for reconditioning (heating or cooling).

- No Adjustable Dampers: Grilles do not usually have dampers, meaning they cannot regulate airflow. They are designed solely for air intake.

Register

- Supply of Conditioned Air: Registers are typically found where the HVAC system supplies conditioned air to the room. They are equipped with adjustable dampers.

- Adjustable Air Flow: The key feature of a register is its ability to control the direction and volume of airflow. The dampers can be manually adjusted, allowing for the regulation of air distribution.

Diffuser

- Even Air Distribution: A diffuser is used on the supply side of an HVAC system, similar to a register. However, its primary function is to evenly distribute the conditioned air across a larger area.

- Specific Design: Diffusers often have a more complex design than registers, featuring multiple vanes or louvers to direct air in various directions. This design helps in spreading the air more evenly and creating more comfortable conditions.

Summary of Differences

- Grille: Used for air return, no dampers, and does not regulate airflow.

- Register: Used for air supply, equipped with adjustable dampers for airflow control.

- Diffuser: Also used for air supply, designed for even air distribution, typically with a more complex and specialized design than registers.

6. HVAC Diffuser vs. Register, How do they Compare?

The primary difference between an HVAC diffuser and a register lies in their functionality and design. A diffuser is focused on even air distribution, while a register offers control over the airflow’s volume and direction. Their appropriate selection and placement are crucial for achieving the desired comfort and efficiency in an HVAC system.

HVAC Diffuser

- Purpose and Function – Designed for Even Air Distribution: A diffuser’s primary function is to evenly distribute conditioned air across a room or space, promoting uniform heating or cooling.

- Design Characteristics – Complex Design for Air Dispersion: Diffusers typically have a more complex design, with vanes or louvers to direct air in multiple directions, facilitating a broad and even spread of air.

- Placement – Used in Ceilings: Diffusers are commonly installed in ceilings, especially in commercial buildings, to maximize the dispersion of air over a wide area.

- Aesthetic Options – Variety of Aesthetic Designs: They often come in various shapes and designs to blend with the architectural aesthetics of a room.

HVAC Register

- Purpose and Function – Controls Airflow Volume and Direction: Registers are used to supply conditioned air to a room, with the ability to control the direction and volume of airflow.

- Design Characteristics – Adjustable Dampers: Registers are equipped with adjustable dampers, allowing users to regulate the amount of air entering a room and its flow direction.

- Placement – Used in Floors, Walls, or Ceilings: They can be installed in various locations, including floors, walls, and ceilings, depending on the design and layout of the HVAC system.

- Control Features – Manual Adjustment for Airflow: The dampers in registers can be manually adjusted to manage room comfort levels more precisely.

Comparison summary

- Functionality: Diffusers are designed for a broad and even distribution of air without the ability to adjust airflow volume, whereas registers allow for direct control over the volume and direction of airflow.

- Design: Diffusers have a complex design to disperse air evenly, whereas registers have simpler designs with functional dampers for airflow control.

- Placement and Aesthetics: Diffusers are often found in ceilings and come in various decorative designs, while registers can be placed on floors, walls, or ceilings and have a more utilitarian appearance.

7. What are HVAC Diffuser & Grille Types?

Let’s check the below video first:

HVAC diffusers and grilles come in various types, each serving specific functions in air distribution. Ceiling, linear, slot, and swirl diffusers are designed for efficient air supply and distribution with different aesthetic and airflow characteristics. Return air grilles, supply air grilles, egg crate grilles, and floor grilles are used for efficient air return and supply with varied designs for different environmental needs.

Types of HVAC Diffusers

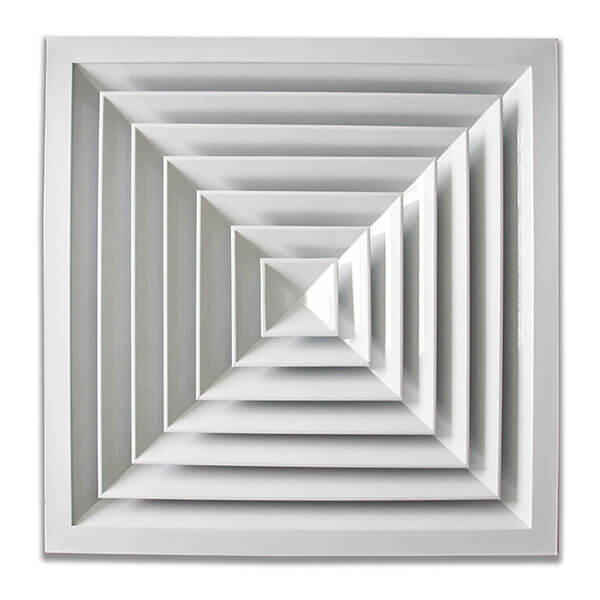

Ceiling Diffusers

- Function: Designed to distribute air from an overhead position, ensuring even air distribution in a room.

- Design Variants: Include square, round, and rectangular shapes, often with adjustable vanes for directional airflow control.

Linear Diffusers

- Function: Provide a continuous, linear air distribution, ideal for large spaces.

- Design Variants: Available in various lengths and are often used in modern or commercial settings for a sleek, unobtrusive look.

Slot Diffusers

- Function: Offer a discreet air distribution solution, with a narrow opening that delivers air in a streamlined manner.

- Application: Commonly used in office and commercial spaces for targeted airflow with minimal visual impact.

Swirl Diffusers

- Function: Create a swirling, turbulent airflow, which helps in the quick mixing of room and supply air for rapid temperature equalization.

- Design Feature: Characterized by their radial design of blades that creates a swirling air pattern.

Types of HVAC Grilles

Return Air Grilles

- Function: Used for air return to the HVAC system for reconditioning; they do not have dampers for airflow control.

- Design Feature: Typically have a simple, open louver design to maximize air return efficiency.

Supply Air Grilles

- Function: Facilitate the delivery of conditioned air into a room but with less emphasis on the precise direction or spread of air compared to diffusers.

- Design Variants: These come in various designs and may include adjustable louvers for basic control of airflow direction.

Egg Crate Grilles

- Function: Named for their egg-crate-like design, these grilles provide high air flow rates and are often used in industrial or commercial settings.

- Application: Ideal for areas requiring maximum air volume efficiency and are often used in exhaust applications.

Floor Grilles

- Function: Specifically designed for floor installation, usually for air supply in a room.

- Design Feature: Built to withstand foot traffic and, in some cases, can be load-bearing.

8. Do all HVAC Systems have Diffusers?

Not all HVAC (Heating, Ventilation, and Air Conditioning) systems necessarily have diffusers. The use of diffusers depends on the system’s size, complexity, and specific air distribution needs. In less complex systems, alternative components like registers, grilles, or direct duct outlets may be used to direct and control airflow.

HVAC Systems with Diffusers

- Centralized Systems: In many centralized HVAC systems, especially in commercial and office buildings, diffusers are commonly used. They are integral in these systems for distributing air evenly throughout large spaces.

- Systems Requiring Even Air Distribution: HVAC systems designed to provide uniform temperature and air quality across a space typically incorporate diffusers. These systems prioritize comfort and efficient air distribution.

HVAC Systems Without Diffusers

- Smaller or Simpler Systems: In smaller or less complex HVAC setups, such as residential systems or those in small buildings, traditional diffusers may not be present. Instead, simpler vents or registers might be used for air distribution.

- Specialized Systems: Certain specialized HVAC systems might use alternative air delivery methods that do not involve standard diffusers. For example, systems designed for specific industrial applications might have customized air delivery mechanisms.

Alternative Air Distribution Components

- Registers and Grilles: Some HVAC systems may use registers and grilles instead of diffusers. Registers allow for basic control over the airflow direction and can be found in both residential and commercial settings.

- Direct Duct Outlets: In simpler HVAC systems, air might be delivered directly through duct outlets without the need for diffusers, especially in areas where precise control over air dispersion is not critical.

9. What is an AC Diffuser Grille?

An AC diffuser grille is a component in air conditioning systems that serves as both an air diffuser and a grille. It is designed to distribute conditioned air evenly throughout a space while also functioning as a decorative cover for the duct opening. This dual-purpose design allows for effective air circulation and temperature control while blending seamlessly with the room’s aesthetics.

10. How to Compare Linear Diffuser vs. Slot Diffuser?

Comparing linear diffusers and slot diffusers in HVAC systems involves understanding their design, functionality, and suitable applications. Both are used for distributing air in a space, but they have distinct features that make them suitable for different environments.

Linear Diffusers

Design Characteristics

- Broad Air Distribution: Linear diffusers have a long, rectangular shape that allows for a wide distribution of air along their length.

- Aesthetic Appeal: Often chosen for their sleek and modern appearance, they can span across a room or along walls, blending with architectural elements.

Airflow Direction

- Multi-directional Airflow: They typically allow for directional control of the air, providing an even distribution across a large area.

Application

- Ideal for Large Spaces: Best used in larger rooms or spaces where even air distribution over a wide area is essential.

Slot Diffusers

Design Characteristics

- Discreet Air Distribution: Slot diffusers are characterized by their narrow, slot-like openings. They provide a more subtle and less obtrusive appearance compared to linear diffusers.

- Integration with Architecture: Often used where architectural integration is a priority. They can blend seamlessly with the ceiling or wall design.

Airflow Direction

- Streamlined Airflow: Slot diffusers typically direct air in a single direction along the length of the slot. They are suitable for targeted airflow, especially in spaces where direct air movement is preferred.

Application

- Versatility in Various Settings: Commonly used in both commercial and residential settings. They are particularly useful in areas where discreet yet effective air distribution is needed.

Comparison summary

- Design and Appearance: Linear diffusers offer a broader design and are more visible, whereas slot diffusers provide a more discreet appearance.

- Airflow Distribution: Linear diffusers are suited for wide air distribution, while slot diffusers offer more streamlined, directional airflow.

- Suitable Applications: Linear diffusers are ideal for larger spaces needing even air coverage, and slot diffusers are preferred for targeted air delivery in spaces where aesthetics are a priority.

11. How do you Calculate Supply Air Diffuser Sizing?

Calculating the sizing for supply air diffusers in HVAC systems is an important process to ensure efficient and effective air distribution in space. The calculation is based on several factors, including the air flow rate required for the space, the type of diffuser, and the room’s layout.

Determine Air Flow Requirements

- Calculate Room Volume: Measure the room’s dimensions to calculate its volume (length x width x height).

- Establish Air Changes Per Hour (ACH): Determine the recommended ACH for the space based on its usage (e.g., living spaces, offices, industrial areas).

- Calculate Air Flow Rate: Multiply the room volume by the ACH to get the cubic feet per minute (CFM) of air required for the space.

Consider Diffuser Efficiency

- Select Diffuser Type: Different diffusers (linear, slot, ceiling) have varying efficiency levels and throw patterns. Select a type based on room layout and aesthetic preferences.

- Manufacturer’s Data: Refer to the manufacturer’s data for the selected diffuser type to understand its performance characteristics.

Account for Room Layout

- Room Shape and Obstructions: Consider the shape of the room and any obstructions (like furniture or partitions) that might affect air distribution.

Calculate Diffuser Size

- Diffuser Performance Data: Using the CFM requirement and the performance data of the diffuser type, calculate the number and size of diffusers needed. This data typically includes information on the diffuser’s effective area and the maximum air flow rate it can handle.

- Distribution of Diffusers: Plan the distribution of diffusers across the room to ensure even air distribution.

Adjust for Specific Conditions

- Special Requirements: Adjust calculations for rooms with high ceilings, large windows, or other specific conditions that might affect heating or cooling requirements.

Consider Aesthetics and Noise

- Design Integration: Ensure the selected diffuser size complements the room’s aesthetics.

- Noise Levels: Larger diffusers can handle higher air volumes at lower velocities, reducing noise levels.

Calculating supply air diffuser sizing involves determining the airflow requirements based on room volume and ACH, considering diffuser efficiency and room layout, using diffuser performance data to calculate the size and number of diffusers, and making adjustments for specific room conditions and aesthetics. Accurate calculation is crucial for effective air distribution, energy efficiency, and occupant comfort. Consulting with HVAC professionals is recommended for precise calculations and system design.

12. Why Does Pressure Increase in an HVAC Diffuser?

The increase in pressure in an HVAC diffuser is primarily due to the dynamics of airflow restriction and acceleration as per fluid dynamics principles. The design of the diffuser, along with various external system factors, contributes to this phenomenon, which is essential for effective air distribution within HVAC systems. Understanding these dynamics helps in optimizing HVAC system design and functionality for efficient heating, ventilation, and air conditioning.

Airflow Restriction

- Narrowing Air Passage: As air flows from the ductwork into the diffuser, the passage through which the air moves often narrows. This constriction in the air passage causes an increase in air velocity, leading to a rise in static pressure within the diffuser.

Principle of Fluid Dynamics

- Bernoulli’s Principle: According to Bernoulli’s Principle in fluid dynamics, when the velocity of a fluid (in this case, air) increases, the pressure also increases. The design of the diffuser naturally accelerates the air, leading to increased pressure.

Air Distribution Design

- Diffuser Blade Design: The design of the diffuser, especially the orientation and structure of its blades or vanes, plays a crucial role in airflow management. The blades direct the air, causing it to accelerate and, consequently, increase in pressure.

System Balancing

- Pressure as a Balancing Mechanism: In HVAC systems, pressure increase is often a deliberate design feature to ensure even distribution of air across all diffusers in a system, especially in larger or more complex setups.

Impact of External Factors

- External System Factors: Factors such as ductwork layout, blockages, bends, and other restrictions in the system can also contribute to pressure changes in diffusers.

13. What is the Difference between a Nozzle and an HVAC Diffuser?

A nozzle and an HVAC diffuser are important in the context of heating, ventilation, and air conditioning (HVAC) systems. Both components play roles in airflow management but are designed for distinct functions. The main difference between a nozzle and an HVAC diffuser lies in their primary function and design – diffusers for even air distribution in space and nozzles for focused, directional air delivery.

HVAC Diffuser

Function and Purpose

- Air Distribution: A diffuser’s primary role in HVAC systems is to distribute conditioned air evenly across a room or space. It ensures a uniform spread of air, contributing to effective room heating or cooling.

Design Characteristics

- Dispersion Pattern: Diffusers often have a complex design with multiple vanes or louvers that direct airflow in various directions, promoting broad and even air distribution.

Placement

- Commonly Used in Ceilings: Diffusers are typically installed in ceilings, especially in residential and commercial buildings, for optimal air circulation.

Application

- Comfort and Efficiency: They are used in HVAC systems that focus on occupant comfort and energy efficiency by providing even temperature distribution and indoor air quality.

Nozzle

Function and Purpose

- Targeted Airflow: A nozzle in HVAC systems is designed to direct airflow in a specific direction with a focused stream. It’s more about directing air than dispersing it.

Design Characteristics

- Streamlined Flow: Nozzles have a design that allows air to exit at higher velocities. This design is conducive to directing air over long distances or to specific areas.

Placement

- Varied Applications: Their placement can vary based on the system’s requirements, and they are not limited to ceiling installations.

Application

- Specialized Use Cases: Nozzles are often used in industrial applications or in spaces where air needs to be directed to hard-to-reach areas or for specific ventilation purposes.

Comparison summary

- Functionality: Diffusers are designed for even air distribution and comfort, whereas nozzles are meant for targeted, directional airflow.

- Airflow Characteristics: Diffusers disperse air evenly with a focus on broad coverage, while nozzles direct air streams to specific points or areas.

- Design and Application: Diffusers have a complex design suitable for general HVAC use in residential and commercial settings, whereas nozzles have a streamlined design for specialized applications, often in industrial environments.

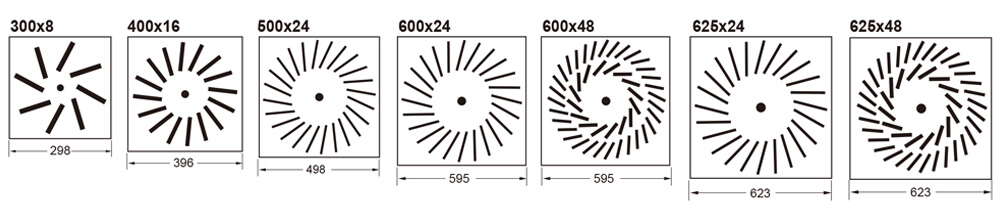

14. What is Common Swirl Diffuser Sizing?

Common swirl diffuser sizing typically ranges in diameter from 6 to 24 inches, but the ideal size for a particular application depends on factors like room size, ceiling height, airflow requirements, and aesthetic considerations. Manufacturers often provide a range of standard sizes as well as custom sizing options to accommodate different needs.

Standard Sizes

- Range of Diameters: Swirl diffusers typically come in a range of standard sizes, with diameters often varying from about 6 inches (150 mm) to 24 inches (600 mm).

Factors Influencing Size Selection

Room Size and Ceiling Height

- Larger rooms or those with higher ceilings may require larger diffusers or multiple smaller ones to ensure adequate air distribution.

Air Flow Requirements

- The required air flow rate (measured in cubic feet per minute, or CFM) for the space will influence the size of the diffuser. Higher CFM requirements may necessitate larger swirl diffusers.

Aesthetic and Architectural Considerations

- The size might also be influenced by aesthetic preferences or architectural constraints within the space.

Custom Sizing

- Tailored to Specific Needs: Apart from standard sizes, manufacturers often offer custom-sized swirl diffusers to meet specific project requirements or to fit unique architectural designs.

Placement and Spacing

- Uniform Coverage: The size of the diffuser also determines its optimal placement and spacing in the ceiling grid. Proper placement ensures uniform air distribution throughout the space.

Manufacturer’s Specifications

- Consulting Product Data: It’s important to refer to the manufacturer’s specifications for detailed information on available sizes and their corresponding airflow capacities.

15. Where Do You Install HVAC Diffusers?

HVAC diffusers are typically installed in ceilings, walls, or floors, depending on the specific requirements of the space, the layout of the HVAC system, and the architectural design of the building. Ceiling installations are most common due to their effectiveness in distributing air evenly, but wall and floor installations are also used based on specific needs and system designs.

Ceiling Installations

- Most Common Location: Ceilings are the most common location for HVAC diffuser installation. This placement allows for efficient and even distribution of conditioned air throughout the room.

- Suitable for Various Room Types: Ideal for both residential and commercial spaces, ceiling diffusers can efficiently disperse air in large rooms or open areas.

Wall Installations

- Targeted Air Distribution: Wall-mounted diffusers are used when targeted air distribution is required, or when ceiling installation is not feasible due to architectural constraints.

- Application in Specific Layouts: Often used in long corridors or areas where ceiling height is a limiting factor.

Floor Installations

- Underfloor Air Distribution: In some modern HVAC systems, especially those that use underfloor air distribution (UFAD), diffusers are installed on the floor. This is particularly common in office buildings with raised flooring systems.

- Efficient in Specific Settings: Floor installations are effective in spaces where the diffuser needs to deliver warm air that rises to heat a room or in areas where ceiling and wall installations are not practical.

Considerations for Diffuser Placement

- Room Function and Layout: The function of the room and its layout, including the placement of furniture and the presence of internal partitions, influence where diffusers should be installed for optimal air distribution.

- Aesthetic Integration: The visual impact of diffusers on the room’s aesthetics should also be considered. Many modern diffusers are designed to blend seamlessly with the room’s decor.

- Accessibility for Maintenance: Diffusers should be installed in locations where they can be easily accessed for maintenance and cleaning.

16. What Does Ceiling Diffuser Do?

A ceiling diffuser in HVAC systems plays a vital role in air distribution within a room or space. Installed in the ceiling, it serves several key functions to enhance the efficiency and comfort of the heating, ventilation, and air conditioning system. It ensures even air distribution, enhances comfort by balancing room temperature and improving air circulation, and is designed to integrate aesthetically with the room while minimizing noise.

Even the Distribution of Air

- Disperses-Conditioned Air: The primary function of a ceiling diffuser is to evenly disperse conditioned air (either cool or warm) that comes through the HVAC system into the room.

- Prevents Direct Airflow: By distributing air across a wide area, ceiling diffusers prevent the discomfort of direct, strong airflow that can occur with more concentrated air outlets.

Enhances Room Comfort

- Balances Room Temperature: By evenly distributing air, ceiling diffusers help maintain a consistent temperature throughout the room, eliminating hot or cold spots.

- Improves Air Circulation: They aid in improving the overall air circulation within a space, contributing to better air quality and comfort.

Aesthetic and Acoustic Considerations

- Blends with Ceiling Design: Ceiling diffusers are often designed to blend with the ceiling’s aesthetics, providing a seamless look that integrates well with the room’s decor.

- Reduces Noise: They are designed to minimize noise from the airflow, ensuring a quiet and comfortable indoor environment.

Efficiency in Air Handling

- Optimizes HVAC System Performance: Properly designed and placed ceiling diffusers help the HVAC system operate more efficiently by ensuring effective air distribution with minimal energy waste.

Versatility in Design

- Variety of Styles and Shapes: Ceiling diffusers come in various shapes, sizes, and styles, such as square, round, or linear, to suit different architectural needs and airflow requirements.

17. What is the Material for the Ceiling Diffuser Damper?

The material for ceiling diffuser dampers in HVAC systems is typically aluminum, galvanized steel, stainless steel, plastic, or various composite materials. The selection depends on factors such as durability, environmental conditions, system requirements, and aesthetic considerations. The right material choice ensures the damper’s effective performance, longevity, and integration with the HVAC system and building design.

Aluminum

- Lightweight and Durable: Aluminum is a popular choice due to its lightweight nature and durability. It resists corrosion, which is essential for long-term use in varying environmental conditions.

Galvanized Steel

- Strength and Resistance: Galvanized steel is another common material, valued for its strength and resistance to rust and corrosion. It’s particularly suitable for environments where the damper may be exposed to moisture.

Stainless Steel

- High Corrosion Resistance: For environments that require extra resistance to corrosion or where higher quality materials are preferred, stainless steel is an excellent option. It combines durability with a more premium look and feel.

Plastic

- Cost-Effective and Rust-Proof: In some applications, especially where cost is a major consideration, plastic dampers can be used. They are rust-proof and lightweight but may not offer the same level of durability as metal options.

Composite Materials

- Innovative Options: Some modern diffusers use composite materials, which can offer a balance between durability, weight, and cost.

Considerations for Material Selection

- Environmental Factors: The choice of material can depend on environmental factors such as humidity, temperature fluctuations, and exposure to chemicals, which might impact the damper’s longevity and functionality.

- System Compatibility: The material should be compatible with the overall HVAC system design, considering factors like airflow, pressure, and system balance.

- Aesthetic Preferences: In visible installations, the material’s appearance can be a consideration, especially in architectural or design-centric projects.

18. What Happens to Lost Kinetic Energy in a Diffuser?

In a diffuser, the lost kinetic energy of air is primarily converted into static pressure. This transformation is crucial for effective and efficient air distribution in HVAC systems. The process involves a decrease in air velocity and a corresponding increase in static pressure, which helps in achieving even and comfortable air distribution while maintaining the overall energy balance within the system.

Transformation of Kinetic Energy

- Reduction in Velocity: As air passes through a diffuser, its velocity decreases. This reduction in airspeed results in a decrease in kinetic energy.

Conversion to Static Pressure

- Increase in Pressure: The kinetic energy of the moving air is transformed into static pressure. According to Bernoulli’s principle, as the velocity of a fluid (air in this case) decreases, its static pressure increases. This increase in static pressure is essential for proper air distribution in HVAC systems.

Energy Balance

- Conservation of Energy: The principle of conservation of energy applies here. The total energy (kinetic plus static) in the air remains constant, barring any losses due to friction or heat exchange. The decrease in kinetic energy is counterbalanced by an increase in static pressure.

Impact on Air Distribution

- Even Distribution: The conversion of kinetic energy to static pressure in a diffuser facilitates the even distribution of air in space. This helps in reducing drafts and ensuring a comfortable indoor environment.

Efficiency of HVAC System

- Optimizing System Performance: By managing the kinetic energy and converting it into useful static pressure, diffusers play a crucial role in optimizing the efficiency of HVAC systems. They ensure that air is delivered effectively to the intended areas without unnecessary energy loss.

19. How do you Choose a Diffuser for the HVAC System?

Choosing a diffuser for an HVAC system involves assessing room requirements, selecting the appropriate type, considering aesthetic preferences, evaluating material and quality, considering noise levels, factoring in energy efficiency, ensuring compatibility with the HVAC system, and seeking professional advice. Proper selection is crucial for achieving optimal air distribution, comfort, and system efficiency.

Assess Room Requirements

- Room Size and Ceiling Height: Consider the dimensions of the room and the height of the ceiling. Larger rooms or those with high ceilings might require diffusers that can distribute air over a wider area.

- Airflow Needs: Determine the volume of air (measured in cubic feet per minute, or CFM) that needs to be distributed in the room. This will influence the size and capacity of the diffuser.

Select the Appropriate Diffuser Type

- Ceiling, Wall, or Floor Diffusers: Choose between ceiling, wall, or floor diffusers based on the layout of the space and the HVAC system design.

- Type of Airflow Pattern: Different diffusers provide different airflow patterns (e.g., linear, radial, swirl). Select a pattern that best suits the air distribution needs of the room.

Consider Aesthetic Preferences

- Design and Appearance: Diffusers come in various designs and finishes. Select a style that complements the interior decor of the space.

Evaluate Material and Quality

- Durability and Maintenance: Consider the material of the diffuser (e.g., metal, plastic). Different materials offer varying levels of durability and ease of maintenance.

Noise Level Consideration

- Acoustic Performance: Some diffusers are designed to minimize noise. If noise is a concern, look for diffusers with low-noise features.

Factor in Energy Efficiency

- System Efficiency: Ensure that the diffuser is compatible with the energy efficiency goals of the HVAC system. Efficient diffusers can contribute to lower energy consumption.

Check Compatibility with HVAC System

- System Integration: The diffuser should be compatible with the existing HVAC system in terms of size, airflow capacity, and control systems.

Consult with Professionals

- Expert Advice: When in doubt, consult with HVAC professionals. Their expertise can guide you in choosing the right diffuser for your specific system and needs.

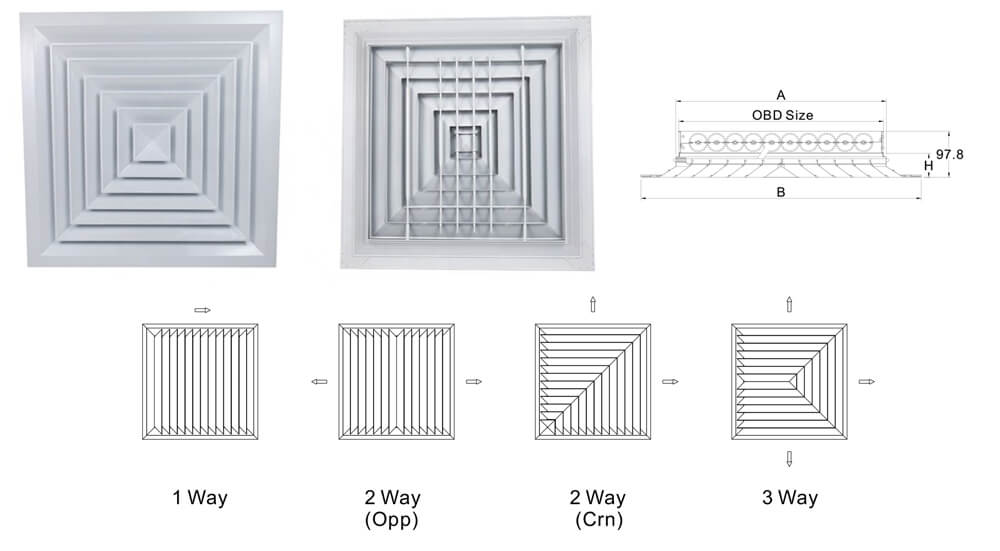

20. What is the Difference between Two-way Diffusers and four-way diffusers?

The difference between two-way and four-way diffusers in HVAC systems lies in their design and the pattern of air distribution they provide. Both types are used to control and direct airflow in a space, but they are suited for different applications based on their air dispersion characteristics. Here’s an explanation of the key differences:

Two-Way Diffusers

Airflow Direction

- Bi-Directional Air Distribution: Two-way diffusers distribute air in two opposite directions. Their design typically allows air to flow linearly in two directions.

Design and Placement

- Linear or Rectangular Shape: These diffusers often have a linear or rectangular design and are placed where air needs to be directed toward two opposite areas.

Suitable Applications

- Ideal for Narrow Spaces: They are particularly effective in elongated or narrow spaces where air needs to be distributed evenly along the length of the room, such as corridors.

Four-Way Diffusers

Airflow Direction

- Quad-Directional Air Distribution: Four-way diffusers disperse air in four different directions, usually in a square or circular pattern. This allows for a more uniform distribution of air across a wider area.

Design and Placement

- Square or Circular Shape: These diffusers typically have a square or circular shape and are installed in central locations within a room to maximize air distribution.

Suitable Applications

- Ideal for Larger, Open Areas: Best suited for larger and more open spaces such as offices, conference rooms, or large living areas where even air distribution is needed in all directions.

Comparison summary

- Directionality of Airflow: The primary difference is in airflow direction – two-way diffusers direct air in two opposite directions, while four-way diffusers distribute air in four different directions.

- Design and Aesthetics: Two-way diffusers often have a more elongated design, whereas four-way diffusers are typically square or circular.

- Application Based on Room Layout: The choice between the two depends on the room’s shape and size, with two-way diffusers being more suitable for narrow or elongated rooms and four-way diffusers being preferred for square or circular rooms requiring even air distribution.

21. What is the Difference between HVAC Grille and Diffuser?

An HVAC grille and a diffuser are essential for proper HVAC system design and functionality. Both are components used in air distribution systems but serve different purposes and have distinct designs. Choosing between a grille and a diffuser depends on the specific needs of the HVAC system – whether the focus is on air intake/return or on the effective distribution of conditioned air within a space.

HVAC Grille

Primary Function

- Air Intake or Return: Grills are typically used for air return to the HVAC system or as air intake vents. They don’t usually have dampers and are not primarily used to control airflow direction.

Design Characteristics

- Simple Slatted Design: Grills often have a simple design, consisting of fixed slats or bars. They can be made from various materials like metal or plastic and come in different sizes and styles.

Airflow Management

- Lack of Adjustable Airflow: Grills do not typically have mechanisms to adjust the airflow since their main function is to facilitate air return to the HVAC system or allow air intake.

HVAC Diffuser

Primary Function

- Distribution of Conditioned Air: Diffusers are used to distribute conditioned air (either cool or warm) throughout a space. They play a crucial role in maintaining comfort levels in a room.

Design Characteristics

- Complex Design for Even Air Dispersion: Diffusers often have a more complex design compared to grills. They are engineered to distribute air evenly, with vanes or louvers to control the direction and spread of airflow.

Airflow Management

- Adjustable Airflow: Many diffusers allow for adjustment of airflow direction and sometimes volume, providing greater control over air distribution in a space.

Comparison Summary

- Purpose and Functionality: The main difference lies in their purpose – grills are used for air intake or return, while diffusers are designed to distribute conditioned air evenly in a room.

- Design and Airflow Control: Grills have a simpler design with fixed slats and no airflow adjustment, whereas diffusers have a more complex design with features to control the direction and pattern of airflow.

- Application in HVAC Systems: Grills are essential for ensuring efficient air circulation back to the HVAC system, while diffusers are crucial for achieving comfort by evenly distributing conditioned air in living spaces.

22. What is a Slot Diffuser?

A slot diffuser is a type of HVAC air distribution device, typically mounted in the ceiling, characterized by one or more long, narrow slots through which air is discharged into a space. Its design allows for a streamlined and unobtrusive way to deliver conditioned air, making it a popular choice for modern and architectural environments. Slot diffusers are valued for their ability to provide an even air distribution while blending seamlessly with the ceiling design.

23. How does a Linear Diffuser Work?

Linear diffusers work by providing a continuous, even distribution of air across a room, with a design that allows for multi-directional airflow. They feature a unique design that sets their apart from other types of diffusers, enabling specific airflow characteristics. Their adjustable features and aesthetic appeal make them suitable for various environments, ensuring efficient air distribution and enhanced comfort.

Design and Structure

- Long and Narrow Profile: Linear diffusers have a long, narrow, and often streamlined appearance. This design allows for a continuous and even air distribution along the length of the diffuser.

Air Distribution Mechanism

- Multi-directional Airflow: Air flows through the HVAC system and enters the linear diffuser, where it is directed in multiple directions, typically along the length of the diffuser. This design ensures a widespread distribution of air, covering more area than traditional square or round diffusers.

Control of Airflow

- Adjustable Slots or Vanes: Many linear diffusers come with adjustable slots or vanes that allow control over the direction and spread of the airflow. This adjustability ensures that air is distributed according to the specific needs of the space.

Application and Effectiveness

- Even and Discreet Air Dispersal: The linear design makes these diffusers particularly effective in spreading air evenly across a room. They are often used in spaces where an unobtrusive, yet efficient, air distribution system is desired.

Aesthetic Integration

- Architectural Compatibility: Linear diffusers are favored in architectural and design-centric environments for their sleek appearance. They can be integrated seamlessly into various ceiling types, including suspended and plasterboard ceilings.

Efficiency and Comfort

- Reduced Drafts and Hot/Cold Spots: The widespread and even air distribution characteristic of linear diffusers helps minimize drafts and eliminate hot or cold spots in a room, contributing to greater overall comfort.

24. What is the Purpose of HVAC Diffusers?

The purpose of HVAC diffusers in heating, ventilation, and air conditioning systems is to effectively distribute conditioned air throughout a room or building. HVAC diffusers are essential for ensuring that the air from the HVAC system is spread evenly and comfortably, contributing to the overall efficiency and comfort of the environment. They are designed to control the direction, spread, and velocity of the air being delivered, helping to maintain consistent temperature and air quality across the space.

25. What is the Difference between an Egg Crate Diffuser and a Jet Nozzle Diffuser?

The difference between an egg crate diffuser and a jet nozzle diffuser lies in their design, airflow characteristics, and typical applications within HVAC systems. Both serve the purpose of air distribution but are suited for different environments and needs. Here’s a comparison of the two:

Egg Crate Diffuser

Design Characteristics

- Grid Pattern: Egg crate diffusers feature a grid or lattice-like pattern, resembling an egg crate. This design allows for a high rate of airflow and is effective in evenly distributing air across a wide area.

Airflow Distribution

- Multi-directional and Even Spread: These diffusers distribute air in multiple directions, providing an even spread over a large area. They are efficient in rooms where a broad dispersion of air is needed.

Applications

- Ideal for General Spaces: Commonly used in offices, retail spaces, and various commercial settings where general air distribution is required.

Jet Nozzle Diffuser

Design Characteristics

- Concentrated Airflow Design: Jet nozzle diffusers have a nozzle-like design that focuses the air into a powerful, concentrated jet. They are often adjustable, allowing for directional control of the airflow.

Airflow Distribution

- Directed and Strong Flow: The design facilitates a directed and strong flow of air, suitable for targeting specific areas or for applications where air needs to be delivered over long distances.

Applications

- Suited for Large or High Spaces: Often used in large or high-ceiling spaces like auditoriums, airports, or industrial facilities, where air needs to be directed over long distances or to specific locations.

Comparison Summary

- Design and Aesthetic: Egg crate diffusers have a grid-like appearance and provide a more general air distribution, while jet nozzle diffusers have a more focused, nozzle-like design for targeted airflow.

- Airflow Characteristics: Egg crate diffusers offer a multi-directional and even spread of air, whereas jet nozzle diffusers provide a more concentrated and strong airflow.

- Suitable Environments: The choice between the two depends on the specific air distribution requirements – egg crate diffusers for even air distribution in standard spaces, and jet nozzle diffusers for targeted air delivery in large or specialized environments.

26. What is an Air Duct Diffuser?

Let’s check one video for review:

An air duct diffuser is a component in HVAC systems that attaches to the ductwork and is designed to distribute conditioned air evenly throughout a room or space. It helps in managing the direction, flow rate, and spread of the air being circulated, contributing to effective and efficient heating, cooling, and ventilation in various settings.

27. Why Use Supply Air Diffuser?

The use of supply air diffusers in HVAC systems is fundamental for achieving even air distribution, enhancing indoor air quality, improving energy efficiency, providing customizable airflow control, integrating with interior design, enhancing comfort, and reducing noise. They are integral components in creating and maintaining a comfortable, healthy, and efficient indoor environment.

Even the Distribution of Conditioned Air

- Uniform Airflow: Supply air diffusers are designed to distribute conditioned air (either cooled or heated) evenly across a room or space, which is vital for maintaining consistent temperature and comfort levels.

Improved Air Quality and Circulation

- Enhanced Ventilation: By facilitating effective air circulation, supply air diffusers help improve indoor air quality, disperse fresh air, and reduce the buildup of pollutants.

Energy Efficiency

- Optimized HVAC Performance: Proper distribution of air via supply diffusers allows the HVAC system to operate more efficiently. This can lead to energy savings and reduced operational costs.

Customizable Airflow Direction

- Adjustable Airflow Control: Many supply air diffusers come with adjustable vanes or louvers, allowing customization of airflow direction to suit the specific needs of different areas within a space.

Aesthetic Integration

- Design Compatibility: Supply air diffusers are available in various designs, sizes, and colors, allowing them to blend seamlessly with the interior aesthetics of a building.

Comfort Enhancement

- Eliminating Hot/Cold Spots: By providing an even distribution of air, supply air diffusers help eliminate hot or cold spots, contributing to a more comfortable indoor environment.

Noise Reduction

- Minimized Acoustic Impact: Advanced diffuser designs can reduce noise levels associated with air distribution, ensuring a quieter and more pleasant indoor atmosphere.

28. How do you Calculate CFM for a Diffuser?

Calculating the cubic feet per minute (CFM) for a diffuser is an important step in ensuring proper air distribution in HVAC systems. CFM measures the volume of air, indicating how much air a diffuser needs to deliver to adequately condition a space.

1. Determine Room Requirements

- Calculate Room Volume: Measure the length, width, and height of the room to calculate its volume (Length x Width x Height).

- Identify Air Changes Per Hour (ACH): Determine the recommended ACH for the space based on its use (e.g., residential, office, industrial). ACH indicates how many times the air should be completely replaced in an hour.

2. Calculate Air Flow Needs

- Calculate Air Flow for the Room: Multiply the room volume by the ACH to determine the total CFM required for the room. This gives the total volume of air that needs to be cycled through the room each hour.

3. Account for Diffuser Efficiency

- Select Diffuser Type: Different types of diffusers (such as linear, slot, or swirl) have varying efficiency levels, which can affect the CFM calculation.

- Manufacturer’s Specifications: Refer to the specifications provided by the diffuser manufacturer. They often include information on the maximum CFM the diffuser can handle effectively.

4. Adjust for Specific Conditions

- Factor in Room Layout: Consider room layout, including ceiling height, the presence of partitions, and furniture, which might impact air distribution and CFM requirements.

- Special Environmental Conditions: Adjust calculations for rooms with specific conditions, like high heat loads or areas with large windows.

5. Divide Total CFM by Number of Diffusers

- Allocate CFM per Diffuser: If the room requires multiple diffusers, divide the total CFM by the number of diffusers to determine the CFM for each one.

6. Consider Safety Margins

- Add a Safety Margin: It’s advisable to add a safety margin to the calculated CFM (around 10-15%) to ensure adequate airflow under varying conditions.

29. What is a Return Air Diffuser?

A return air diffuser is a component in HVAC systems designed to facilitate the return of air back into the system for reconditioning. It is typically a grille or vent through which air from the room is drawn back into the HVAC system, where it is either heated, cooled, or filtered before being recirculated. Return air diffusers are essential for maintaining efficient airflow and air quality in a space.

30. Where Should the Return Air Diffusers be Located?

Return Air diffusers in an HVAC system should be strategically located to ensure efficient air circulation. Ideally, they should be placed in central areas of a building, such as hallways or living rooms, to facilitate the return of air to the HVAC system. In rooms with both heating and cooling needs, consider having high and low placements to capture warm air that rises and cool air that settles near the floor. It’s also important to ensure that return diffusers are not obstructed by furniture or other barriers to maintain effective airflow.

31. Does Every Room Require a Return Air Diffuser?

Not every room in a building necessarily requires a dedicated return air diffuser for an HVAC system to function effectively. The requirement for return air diffusers in individual rooms depends on several factors including the size and layout of the space, the overall design of the HVAC system, and specific airflow requirements.

In many residential and smaller commercial settings, a central return air diffuser may suffice, especially if there are adequate door undercuts or transfer grilles to allow air to flow back to the central return from individual rooms.

In larger or more complex buildings, however, having return air diffusers in individual rooms can enhance air circulation, improve indoor air quality, and contribute to more efficient heating and cooling.

32. Is there a Difference between a Return Air Diffuser and an Exhaust Air Diffuser?

Yes, there is a difference between a return air diffuser and an exhaust air diffuser in HVAC systems. The key difference lies in their roles – return air diffusers recycle air back into the HVAC system for continued indoor use, while exhaust air diffusers remove air from the building as part of the ventilation process.

Return Air Diffuser

- Purpose: A return air diffuser is designed to facilitate the return of indoor air back into the HVAC system for reconditioning (heating, cooling, or filtering).

- Location: Typically located in central areas or strategically in individual rooms, it helps maintain efficient air circulation within the indoor environment.

- Air Quality Maintenance: By drawing room air back into the system, it contributes to maintaining consistent indoor air quality and temperature.

Exhaust Air Diffuser

- Purpose: An exhaust air diffuser is used to expel air from inside a building to the outside. It is crucial in removing stale, contaminated, or humid air from indoor spaces.

- Location: Often found in bathrooms, kitchens, or industrial areas where air quality can be compromised due to moisture, odors, or pollutants.

- Ventilation Focus: Its primary role is in ventilation, ensuring the removal of undesirable air elements from indoor environments.

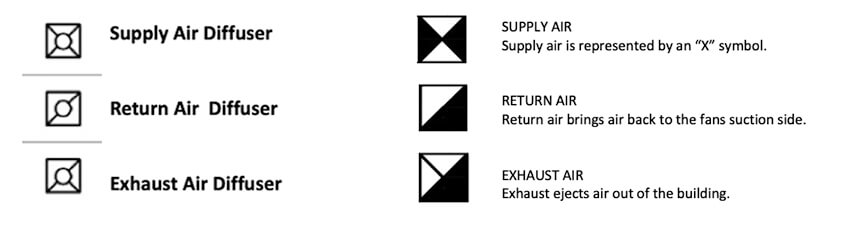

33. What is the Return Air Diffuser Symbol?

The return air diffuser symbol in HVAC plans and diagrams often appears as a rectangular or circular shape with a series of parallel lines or a curved arrow pointing inward, symbolizing the direction of air being drawn into the HVAC system.

34. How do you Choose Material for an HVAC Diffuser System?

When choosing material for an HVAC diffuser system, consider environmental compatibility, durability, aesthetic requirements, cost, efficiency, weight, and compliance with safety regulations. The right material selection ensures the diffuser system is effective, long-lasting, and harmoniously integrated into the space.

1. Environmental Compatibility

- Indoor Air Quality: Materials should not emit harmful substances or odors, especially in sensitive environments like hospitals or schools.

- Humidity and Temperature: Select materials that can withstand the specific humidity and temperature conditions of the space.

2. Durability and Maintenance

- Longevity: Opt for materials known for their durability to ensure the diffuser lasts as long as the HVAC system.

- Maintenance Requirements: Consider how easy the material is to clean and maintain. Some materials may require more frequent cleaning or specific maintenance procedures.

3. Aesthetic Considerations

- Interior Design Compatibility: The material should complement the aesthetic of the room. For instance, aluminum or stainless steel diffusers can offer a modern look, while plastic diffusers can be made in various colors to match different decors.

4. Cost Effectiveness

- Budget: Factor in the cost of the material. More durable or aesthetically pleasing materials might be more expensive, so balance cost with other requirements.

5. Efficiency and Performance

- Air Flow Efficiency: The material should facilitate efficient airflow. It shouldn’t impede the diffuser’s ability to distribute air evenly throughout the room.

- Noise Reduction: Some materials can help reduce noise from airflow, which might be a consideration for spaces like offices or bedrooms.

6. Weight and Installation

- Structural Considerations: Consider the weight of the material, especially for ceiling-mounted diffusers, as it can impact the ease of installation and the structural requirements of the building.

7. Fire Safety and Regulations

- Fire Resistance: In certain environments, fire-resistant materials may be required by law. Always check local building codes and fire safety regulations.

35. What Causes AC Vents to Sweat?

AC vent sweating is caused by a combination of high humidity, significant temperature differences between the air and the vent, lack of proper insulation, overcooling, and potential airflow issues. Addressing these factors can help reduce or eliminate the problem. It’s also advisable to consult with HVAC professionals if the issue persists, as prolonged condensation can lead to other problems like mold growth or damage to surrounding areas.

The phenomenon of “sweating,” or condensation typically occurs when:

1. High Humidity Levels

- Moisture in the Air: When the air is humid, there’s a high concentration of moisture. If this moist air comes into contact with the cooler surface of AC vents, it can condense, leading to the appearance of sweating on the vents.

2. Temperature Differential

- Cool Vents, Warm Air: Condensation occurs when the temperature of the AC vent is lower than the dew point of the surrounding air. In simple terms, the cooler surface of the vent causes moisture in the warmer air to condense on its surface.

3. Lack of Insulation

- Poor Insulation Around Ductwork: If the ductwork leading to the vents is not adequately insulated, the cold air traveling through the ducts can cause the vent surfaces to cool down significantly, exacerbating the condensation issue.

4. Overcooling

- AC System Set Too Low: Setting the air conditioner to a very low temperature can increase the temperature difference between the air and the vent surface, leading to more condensation.

5. Airflow Restrictions

- Blocked or Restricted Vents: If vents are blocked or airflow is restricted, it can cause uneven cooling and areas of moisture buildup, leading to sweating.

36. Where Should You Use the Jet Nozzle Diffuser?

Jet nozzle diffusers are optimal for use in large, open, or high-ceiling spaces where directed and powerful airflow is needed. They are particularly suitable for industrial, commercial, and public spaces that require effective air distribution over long distances or targeted to specific areas. Their design and functionality make them an excellent choice for maintaining comfort and air quality in expansive and high-demand environments.

Large or High-Ceiling Spaces

- Auditoriums, Theaters, and Halls: These areas benefit from jet nozzle diffusers due to their ability to direct air over long distances, ensuring even air distribution in large spaces.

Industrial and Commercial Settings

- Warehouses and Factories: Jet nozzle diffusers are effective in environments with high ceilings or large open areas where focused air delivery is necessary.

Transport Hubs

- Airports and Train Stations: In large and often crowded spaces like these, jet nozzle diffusers can provide efficient air circulation, maintaining comfort even in expansive areas.

Sports and Leisure Facilities

- Gyms and Indoor Arenas: These facilities require efficient air distribution to large areas, which jet nozzle diffusers can provide without creating uncomfortable drafts.

High Demand Areas

- Shopping Malls and Exhibition Centers: In spaces with varying occupancy levels and large footprints, jet nozzle diffusers can ensure comfortable and targeted air distribution.

Areas Requiring Spot Cooling or Heating

- Specific Sections within a Larger Space: Jet nozzle diffusers can be used for spot cooling or heating in certain areas within a larger space, providing localized comfort without affecting the entire area.

37. How to install an HVAC Supply Register and connect the Flex Duct

Let’s watch one video for reference:

Installing an HVAC supply register and connecting it to a flex duct involves a series of steps that require attention to detail to ensure proper airflow and system efficiency. Here’s a guide:

Tools and Materials Needed

- Screwdriver

- Flex duct

- Duct tape or foil tape

- Cable ties or duct straps

- HVAC register

- Drill (if needed for mounting the register)

Step-by-Step Installation Guide

1. Prepare the Installation Area

- Location: Identify the location where the register will be installed. This is typically in the ceiling, wall, or floor, depending on the layout of the room and the HVAC system.

2. Attach the Flex Duct to the HVAC System

- Secure Connection: Connect one end of the flex duct to the main supply plenum or duct branch. Secure this connection using duct tape or foil tape and reinforce it with cable ties or duct straps to ensure an airtight seal.

3. Route the Flex Duct to the Register Location

- Avoid Sharp Bends: Carefully extend the flex duct to the location where the register will be installed. Avoid sharp bends or kinks in the duct, as these can restrict airflow.

4. Prepare the Register

- Open the Dampers: Ensure that the dampers on the register are open for airflow. Some registers come with adjustable dampers to control the airflow volume.

5. Attach the Flex Duct to the Register

- Firm Attachment: Fit the open end of the flex duct over the backside of the register. Secure it in place using duct tape or foil tape, and reinforce the connection with cable ties or duct straps.

6. Mount the Register

- Secure in Place: Fit the register into the prepared opening in the wall, ceiling, or floor. Use screws to secure the register in place. Ensure it is firmly attached and that there are no gaps around the edges.

7. Test the System

- Check Airflow: Turn on the HVAC system and check for proper airflow from the newly installed register. Listen for any unusual sounds that might indicate a leak or poor connection.

Safety and Efficiency Tips

- Wear Gloves: When working with flex ducts and metal edges, it’s advisable to wear gloves to protect your hands.

- Ensure Straight Runs: For maximum efficiency, ensure the flex duct runs as straight as possible with minimal bends.

- Check for Leaks: After installation, inspect all connections for possible air leaks and seal them if necessary.

38. What are Common Materials for HVAC Diffusers?

The choice of material for HVAC diffusers depends on factors such as environmental conditions, aesthetic preferences, budget, and specific application requirements. Aluminum, steel, plastic, stainless steel, and composite materials are all common choices, each offering unique benefits and characteristics suitable for different HVAC needs.

Aluminum

- Lightweight and Corrosion-Resistant: Aluminum is widely used due to its lightweight nature and resistance to corrosion. It’s suitable for various environments and often used for its sleek, modern appearance.

Steel

- Durability and Strength: Steel, especially galvanized steel, is chosen for its durability and strength. It’s ideal for industrial or heavy-duty applications and can be coated for additional corrosion resistance.

Plastic

- Versatility and Cost-Effectiveness: Plastic diffusers are common due to their versatility and lower cost. They can be molded into various shapes and sizes and are available in different colors for aesthetic purposes.

Stainless Steel

- Premium Look and High Resistance: Stainless steel is used for its premium look and high resistance to rust and corrosion. It’s particularly beneficial in environments that require a combination of durability and a more refined appearance.

Composite Materials

- Innovative Options: Some modern diffusers use composite materials for a balance between durability, weight, and cost, as well as for specific design requirements.

39. What is the Advantage of a Stainless-steel Diffuser?

Stainless steel diffusers offer durability, aesthetic appeal, ease of cleaning, temperature resistance, suitability for various environments, and long-term cost-effectiveness. The use of stainless steel in HVAC diffusers offers several advantages, making it a preferred material choice in certain applications.

Durability and Longevity

- High Strength: Stainless steel is known for its strength and durability, which makes stainless-steel diffusers robust and long-lasting.

- Resistance to Corrosion: The material is highly resistant to rust and corrosion, making it ideal for environments with moisture or chemical exposure.

Aesthetic Appeal

- Modern and Sleek Appearance: Stainless steel has a sleek, modern look that can enhance the aesthetic appeal of a space. Its shiny and clean appearance is often sought after for contemporary design schemes.

Hygiene and Cleanliness

- Easy to Clean: The smooth surface of stainless steel is easy to clean and disinfect, which is crucial in maintaining indoor air quality, particularly in sensitive environments like hospitals and commercial kitchens.

Temperature Resistance

- Withstands High Temperatures: Stainless steel can withstand high temperatures, making it suitable for diffusers in heating systems or in areas where temperature variations are significant.

Environmental Compatibility

- Suitable for Various Environments: The material’s resistance to various environmental factors makes it suitable for a wide range of applications, from residential to industrial settings.

Long-Term Cost-Effectiveness

- Low Maintenance: Due to its durability and resistance to damage, stainless-steel diffusers can be more cost-effective in the long term, despite a higher initial investment.

40. What is the Advantage of a Wooden Air Diffuser?

Wooden air diffusers provide aesthetic appeal, environmental friendliness, insulating properties, and customization options, and add a sense of warmth and comfort to indoor spaces. These advantages make them a suitable choice for spaces where design and natural materials are prioritized. However, it’s important to consider factors like durability, maintenance, and cost when opting for wooden diffusers.

Aesthetic and Design Appeal

- Natural Beauty: Wooden diffusers bring a natural, warm aesthetic to a space, making them a popular choice in design-centric environments or spaces where a natural look is desired.

- Versatility in Style: Wood can be finished in various stains and paints, allowing it to fit a wide range of interior designs, from rustic to modern.

Environmental Friendliness

- Eco-Friendly Option: Wood is a renewable resource, and when sourced sustainably, wooden air diffusers can be an environmentally friendly choice.

Insulating Properties

- Natural Insulator: Wood has natural insulating properties, which can slightly aid in reducing heat loss or gain through the diffuser.

Customization and Craftsmanship

- Unique Customization: Wooden diffusers can be crafted to fit unique sizes or shapes, offering a level of customization that might not be as easily achievable with metal or plastic diffusers.

Comfort and Warmth

- Adds Warmth to Spaces: Beyond physical warmth, wood adds a psychological sense of warmth and comfort to spaces, which can be beneficial in residential settings or hospitality environments like hotels and restaurants.

41. What is the Advantage of the Aluminum Diffuser?

The advantage of using an aluminum diffuser lies in its combination of lightweight and durable properties, resistance to corrosion, aesthetic versatility, efficient heat transfer, recyclability, and overall cost-effectiveness. Aluminum diffusers in HVAC systems offer a range of advantages due to the inherent properties of aluminum. These benefits make aluminum diffusers a popular choice in various settings.

Lightweight and Durable

- Ease of Handling and Installation: Aluminum’s lightweight nature makes diffusers easier to handle and install, particularly in ceiling applications.

- Longevity: Despite being lightweight, aluminum is durable and resistant to physical damage, ensuring a long lifespan for the diffuser.

Corrosion Resistance

- Suitability in Varied Environments: Aluminum is naturally resistant to corrosion, making it suitable for use in environments with varying levels of humidity and other corrosive elements.

Aesthetic Versatility

- Modern Appearance: Aluminum diffusers often have a sleek and modern appearance, making them suitable for contemporary interior designs.

- Finish Options: They can be finished in various colors and textures to complement different architectural styles and interior decors.

Thermal Conductivity

- Efficient Heat Transfer: Aluminum’s good thermal conductivity assists in the efficient transfer of heating or cooling energy from the HVAC system to the room.

Recyclability

- Eco-Friendly: Aluminum is highly recyclable, reducing the environmental impact over the lifecycle of the diffuser.

Cost-Effectiveness

- Affordable and Efficient: Compared to other metals, aluminum diffusers are generally more cost-effective, providing a good balance between performance, durability, and price.

42. What are the Advantages of Plastic Grilles and Diffusers?

The advantages of plastic grilles and diffusers include their cost-effectiveness, lightweight and easy installation, corrosion resistance, design versatility, low maintenance, durability, and insulative properties. These benefits make them a suitable choice for a variety of HVAC applications, particularly where budget, aesthetics, and low maintenance are key considerations.

Cost-Effectiveness

- Affordability: Plastic grilles and diffusers are generally more affordable than those made from materials like aluminum or steel, making them a cost-effective choice for budget-conscious projects.

Lightweight and Easy to Install

- Ease of Handling: Their lightweight nature makes them easier to handle and install, particularly in ceiling or high-wall applications.

Corrosion Resistance

- Suitable for Humid Environments: Plastic is naturally resistant to corrosion, making these grilles and diffusers suitable for use in environments with high humidity or exposure to corrosive elements.

Versatility in Design

- Variety of Styles and Colors: Plastic can be molded into various shapes and sizes and can be produced in a wide range of colors to match different interior designs.

Low Maintenance

- Easy to Clean and Maintain: Plastic surfaces are easy to clean and maintain, which is beneficial in maintaining indoor air quality and ensuring the longevity of the product.

Durability

- Resistant to Dents and Scratches: Plastic grilles and diffusers can be quite durable, resisting dents, scratches, and general wear and tear.

Insulation Properties

- Reduced Heat Conductivity: Unlike metal grilles and diffusers, plastic ones do not conduct heat as much, which can slightly improve the overall energy efficiency of the HVAC system.

43. What are the Standard Shapes for HVAC Diffusers?

The standard shapes for HVAC diffusers – square, rectangular, circular, linear, swirl, and perforated – cater to a range of functional and aesthetic requirements. The choice of shape largely depends on the specific application, the desired airflow pattern, and the overall design of the space where the diffuser will be installed. Here are some of the common shapes:

Square and Rectangular Diffusers

- Widespread Use: These are the most common shapes, widely used in both residential and commercial settings.

- Versatility: Suitable for a variety of room sizes and layouts, providing even air distribution.

Circular or Round Diffusers

- Aesthetic Appeal: Often chosen for their aesthetic appeal, circular diffusers can blend well with certain architectural styles.

- Targeted Airflow: Ideal for directing airflow in more concentrated areas.

Linear or Slot Diffusers

- Streamlined Design: These have a long, narrow profile and are often used in modern or architectural environments.

- Even Air Distribution: Effective for providing a continuous and even air spread, especially in larger spaces.

Swirl Diffusers

- Radial Air Pattern: Designed to deliver air in a swirling pattern, enhancing mixing and distribution.

- Efficient in Temperature Control: Particularly effective in spaces requiring rapid mixing of air to maintain consistent temperatures.

Perforated Diffusers

- Discreet Appearance: Feature a perforated face for a more subtle, less obtrusive look.

- Even and Gentle Airflow: Ideal for spaces where a gentle dispersion of air is needed.

44. What is the Advantage of Round Ceiling Diffuser?

The advantage of using a round ceiling diffuser lies in its aesthetic appeal, efficient air distribution, versatility in application, ease of installation, adjustable airflow, quieter operation, and durability. These attributes make it a suitable choice for both functional and aesthetic purposes in a variety of indoor environments.