Basic Introduction of HVAC Air Disc Valves

At AIREVERPEAK(XinSheng), we’re dedicated to crafting HVAC Air Disc Valves that stand out in the market. Our focus is on creating products that meet your specific needs.

Our Air Disc Valves are built to last, using top-quality materials. This means they’re not just durable but also enhance airflow efficiency – saving energy and improving air quality.

Our commitment to quality is backed by various certifications, including the European Union CE, United States UL, and ISO standards. We’re recognized for our high standards in the industry.

- Superior Air Distribution: Our disc valves ensure even and efficient air distribution, eliminating hot and cold spots in your space.

- Robust Build Quality: Crafted with the finest materials, they are built to last, offering exceptional value over time.

- Aesthetic Appeal: With sleek designs, they seamlessly blend into your decor, enhancing the look of your space.

- Easy Maintenance: Designed for convenience, our disc valves are incredibly easy to clean and maintain.

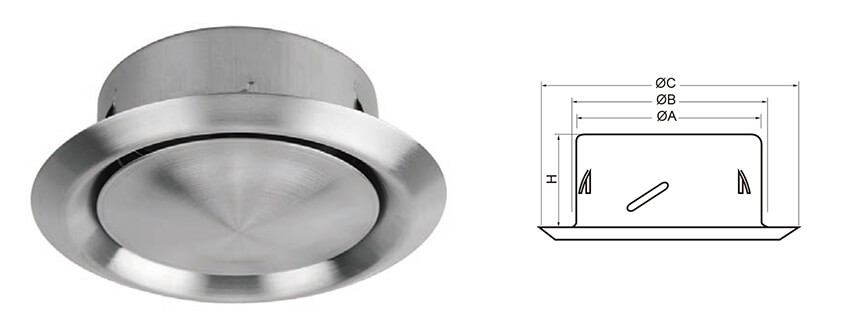

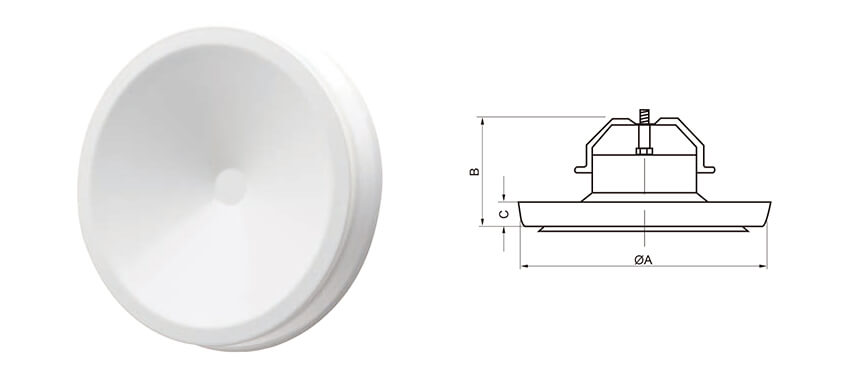

Specification:

- Material: Aluminum, Stainless steel, Galvanized steel, Polypropylene (PP).

- Finish: RAL9010, RAL9016, or RAL 9003 as per customer request.

- The valve body is equipped with a cellular plastic gasket to form an air-tight seal.

- The airflow is adjusted by rotating the control disc.

Basic styles and sizes of HVAC Air Disc Valves

If you want to know more, please click below:

- HVAC Linear Slot Diffusers – The Ultimate Guide

- HVAC Egg Crate Diffuser – The Ultimate Guide

- HVAC Jet Nozzle Diffuser – The Ultimate Guide

- HVAC Linear Bar Grilles – The Ultimate Guide

- HVAC Air Swirl Diffusers – The Ultimate Guide

- HVAC Round Ceiling Diffusers – The Ultimate Guide

- Round Ceiling Diffusers – The Ultimate Guide

- HVAC Return Air Grille – The Ultimate Guide

- Exhaust Air Louver – The Ultimate Guide

- HVAC Registers – The Ultimate Guide

HVAC Air Disc Valves – The Ultimate Guide

1. What are HVAC air disc valves, and how do they work?

HVAC air valves are key components in air conditioning and heating systems, responsible for regulating airflow. They adjust the amount and direction of air entering different spaces, ensuring efficient temperature control and air quality. Available in various types to suit different settings, these valves are essential for maintaining the right balance in your HVAC system, contributing quietly yet significantly to your comfort and energy efficiency.

- Design: Air disc valves are circular or disc-shaped valves that regulate airflow in HVAC systems. They are typically made of metal or plastic and come in various sizes.

- Placement: These valves are commonly installed in ceilings or walls and are particularly used in spaces requiring precise airflow control.

How Do They Work?

- Air Flow Regulation: The central mechanism of an air disc valve is to regulate airflow. This is achieved through the adjustment of the central disc, either manually or automatically.

- Adjustable Disc: The disc can be rotated or moved to increase or decrease the opening, allowing more or less air to pass through.

- Balancing Air Pressure: By controlling airflow, these valves help in balancing air pressure within the room, ensuring efficient distribution of heated or cooled air.

Key Functions of Air Disc Valves

- Supply and Exhaust: They are used for both air supply (bringing fresh air in) and exhaust (expelling stale air out) functions.

- Precise Control: Offers precise control over the volume and direction of airflow, which is crucial in areas like bathrooms, kitchens, or laboratories where ventilation needs are specific.

- Aesthetic Integration: Often designed to blend with the room’s aesthetics, they can be painted or finished to match the interior decor.

2. What are the key benefits of using air disc valves in an HVAC system?

Air disc valves play a pivotal role in the functionality of HVAC (Heating, Ventilation, and Air Conditioning) systems. Their unique design and operation bring several benefits that enhance the overall performance and efficiency of these systems.

1. Precise Air Flow Control

- Customizable Ventilation: Air disc valves allow for precise control over the amount and direction of airflow, which is essential in maintaining a comfortable indoor environment.

- Suitable for Varied Spaces: This precision makes them ideal for use in rooms with specific ventilation needs, like bathrooms, kitchens, or laboratories.

2. Energy Efficiency

- Reduced Energy Consumption: By efficiently regulating airflow, air disc valves contribute to reducing the overall energy consumption of the HVAC system.

- Balanced Air Distribution: They help in evenly distributing air, ensuring that the system works effectively without overburdening any part, leading to energy savings.

3. Easy Installation and Maintenance

- Simple Setup: Air disc valves are generally straightforward to install, making them a convenient choice for both new and existing buildings.

- Low Maintenance: Once installed, they require minimal maintenance, which is a significant advantage in terms of cost and time savings.

4. Enhanced Indoor Air Quality

- Improved Ventilation: By regulating the air supply and exhaust efficiently, these valves help maintain optimal indoor air quality.

- Removal of Contaminants: This is particularly beneficial in spaces where the removal of contaminants and stale air is crucial.

5. Aesthetic Flexibility

- Design Integration: Air disc valves come in various designs and can be customized to blend with or complement the interior decor.

- Color Customization: They can be painted or finished to match the surrounding area, maintaining aesthetic coherence in the space.

6. Versatility in Application

- Wide Range of Use: These valves are suitable for a diverse range of environments, from residential to commercial and industrial settings.

- Adaptability: They can be used in both new constructions and retrofit projects, demonstrating their adaptability to different scenarios.

3. How do air disc valves differ from other types of HVAC valves?

In the realm of HVAC (Heating, Ventilation, and Air Conditioning) systems, various types of valves are used to control airflow and temperature. Among these, air disc valves have distinct characteristics that set them apart from others.

Air Disc Valves: Unique Features

- Design Specificity: Air disc valves are circular or disc-shaped, a design that is particularly efficient for precise airflow control. This shape allows for easy adjustment of air volume and direction.

- Functionality: Primarily used for air supply and exhaust in smaller, targeted areas, they offer a high level of control over the air entering or leaving a space.

- Adjustment Mechanism: The central disc can be rotated to increase or decrease the opening, providing a simple yet effective way to regulate airflow.

Contrasting with Other HVAC Valves

- Butterfly Valves

- Broad Application: Used for regulating flow in larger ducts and are not as precise as air disc valves.

- Different Mechanism: Utilize a flat circular plate in the duct which pivots to open or close.

- Gate Valves

- On/Off Function: Mainly used for shutting off the flow entirely, not for regulating it.

- Different Structure: Consists of a gate that moves up and down, rather than a rotating disc.

- Globe Valves

- Flow Regulation: Used for regulating flow, but with a different mechanism involving a movable plug and a stationary ring seat.

- Bulkier Design: Typically larger and more complex than air disc valves.

Benefits Unique to Air Disc Valves

- Precision Control: Particularly effective in areas where precise air distribution is needed.

- Space Efficiency: Their compact design makes them suitable for installation in limited spaces.

- Aesthetic Integration: Easily customized to blend with the room’s aesthetics.

Air disc valves serve a specialized role in HVAC systems, offering precise control in a compact, aesthetically pleasing design. While other types of valves like butterfly, gate, and globe valves have their specific uses, air disc valves stand out for their ability to finely tune airflow in smaller, focused areas, making them an essential component in modern HVAC systems.

4. Can air disc valves be used in both residential and commercial HVAC systems?

Air disc valves are a versatile component in the HVAC (Heating, Ventilation, and Air Conditioning) world, known for their precise airflow control. Their adaptability makes them suitable for a variety of settings, including both residential and commercial environments.

Use in Residential HVAC Systems

- Enhanced Air Quality: In homes, air disc valves help maintain optimal indoor air quality by regulating fresh air intake and exhaust.

- Customizable Comfort: Their ability to precisely control airflow allows for customized comfort in different areas of a home.

- Space Efficiency: Due to their compact size, air disc valves are ideal for residential spaces where ductwork and installation space might be limited.

Application in Commercial HVAC Systems

- Large-Scale Air Management: Commercial settings like offices, malls, or hospitals require efficient air management. Air disc valves facilitate this by controlling airflow in specific areas or rooms.

- Energy Efficiency: In larger buildings, energy efficiency is crucial. Air disc valves contribute to reducing energy consumption by optimizing air distribution.

- Adaptability to Diverse Environments: Their ability to be customized in terms of design and airflow capacity makes them well-suited for the varied requirements of commercial spaces.

Advantages Across Both Domains

- Precision Control: Whether in a home or a business, the precise control offered by air disc valves ensures comfortable and healthy indoor environments.

- Ease of Installation and Maintenance: Their simple design allows for easy installation and low maintenance, beneficial in both residential and commercial contexts.

- Customization: Available in various sizes and finishes, air disc valves can be tailored to suit the aesthetic and functional needs of any space.

5. What materials are typically used to manufacture air disc valves?

The performance and durability of air disc valves in HVAC systems are heavily influenced by the materials used in their manufacture. Selecting the right material is crucial for ensuring efficiency, longevity, and functionality.

Common Materials for Air Disc Valves

- Aluminum

- Lightweight and Durable: Aluminum is favored for its combination of lightness and strength. It’s often used for air disc valves in both residential and commercial settings.

- Corrosion Resistance: Offers good resistance to corrosion, making it suitable for various environmental conditions.

- Steel

- Robustness: Steel, especially stainless steel, is chosen for its robustness and ability to withstand harsh conditions.

- Heavy-Duty Applications: Ideal for commercial or industrial environments where durability is a priority.

- Plastic

- Cost-Effectiveness: Plastic is a more economical option and is used in less demanding applications.

- Versatility in Design: Allows for a variety of colors and finishes, providing flexibility in aesthetic choices.

- Brass

- Aesthetic Appeal: Brass is often selected for its aesthetic qualities, adding a touch of elegance to the valve design.

- Good Corrosion Resistance: It also offers decent resistance to corrosion and is suitable for visible installations where appearance matters.

Factors Influencing Material Selection

- Environmental Considerations: The choice of material can depend on the environmental conditions, such as humidity, temperature, and exposure to chemicals.

- Mechanical Requirements: Load-bearing capacity and durability needs also influence the choice of material.

- Cost Constraints: Budget limitations play a role in material selection, balancing cost with performance requirements.

6. How do air disc valves contribute to energy efficiency in HVAC systems?

Improving energy efficiency in HVAC systems is crucial for reducing costs and environmental impact. Air disc valves, known for their precise airflow control, play a significant role in this process. This guide will walk you through how to use these valves effectively for energy efficiency.

Step 1: Precise Airflow Adjustment

- Understand Valve Operation: Familiarize yourself with how the air disc valve adjusts airflow. The central disc can be rotated to increase or decrease the air passage.

- Optimize Air Distribution: Adjust the valves to ensure air is directed exactly where needed, preventing overcooling or overheating in unoccupied areas.

Step 2: Implement Balanced Ventilation

- Balance Air Exchange: Set up the air disc valves to balance the intake of fresh air and exhaust of stale air, maintaining an efficient air exchange.

- Monitor Indoor Air Quality: Regularly check air quality to ensure the system isn’t overworking to compensate for poor air conditions.

Step 3: Zone Control Enhancement

- Identify Zones: In a zoned HVAC system, use air disc valves to control airflow in specific areas. This is particularly effective in buildings with varying occupancy levels.

- Adjust Valves Per Zone: Customize airflow in each zone depending on usage, reducing energy wastage in less frequented areas.

Step 4: Regular Maintenance

- Clean Valves Regularly: Keep air disc valves clean to ensure they operate efficiently and do not obstruct airflow.

- Check for Wear and Tear: Periodically inspect the valves for any signs of damage or wear that might affect their performance.

Step 5: Upgrade to Automated Systems

- Consider Automated Valves: For advanced efficiency, upgrade to automated air disc valves that can adjust airflow based on real-time data like occupancy levels or air quality.

Step 6: Professional Consultation

- Seek Expert Advice: If unsure, consult with an HVAC professional to optimize the setup of air disc valves for maximum energy efficiency.

7. Are there different sizes and specifications of air disc valves available?

Yes, you can check them on our website.

Exploring the Range of Sizes and Specifications in Air Disc Valves

1. Variety in Sizes:

- Standard Sizes: Air disc valves are available in standard sizes, typically ranging from small diameters (such as 100mm or 4 inches) to larger sizes (up to 200mm or 8 inches or more). The size required depends on the airflow needs of the space.

- Custom Sizes: For unique ventilation requirements or specific architectural designs, custom-sized air disc valves can be manufactured to meet exact specifications.

2. Specification Differences:

- Material Variations: Air disc valves are made from different materials, including galvanized steel, aluminum, and plastic, each offering distinct benefits in terms of durability, weight, and aesthetic appeal.

- Adjustable Features: Many models come with adjustable features, allowing control over the airflow and direction. This adaptability makes them suitable for a variety of environments.

3. Application-Based Specifications:

- Residential vs. Commercial: The specifications for air disc valves can vary greatly between residential and commercial applications. Commercial settings might require larger sizes and more robust materials due to higher airflow demands.

- Specialized Environments: In areas with specific requirements, such as laboratories or hospitals, air disc valves may have specialized specifications for air quality control and safety.

8. How do I choose the right size and type of air disc valve for my HVAC system?

Choosing the correct size and type of air disc valve is crucial for the efficiency and effectiveness of your HVAC system. This guide will help you navigate the selection process, ensuring you find a valve that fits your specific requirements.

Step 1: Assessing Room Size and Airflow Requirements

- Room Dimensions: Consider the size of the space where the valve will be installed. Larger rooms may require valves with a larger diameter to handle increased airflow.

- Airflow Needs: Determine the volume of air that needs to be circulated. This is crucial for selecting a valve that can efficiently manage the required airflow.

Step 2: Understanding Duct Sizing

- Duct Dimensions: Measure the size of the ductwork in your HVAC system. The valve size should correspond to these measurements to ensure a proper fit.

- Duct Compatibility: Ensure that the valve type you choose is compatible with your existing ductwork in terms of size and installation requirements.

Step 3: Considering the Valve Material

- Environmental Factors: Choose a material that suits the environment where the valve will be used. For instance, stainless steel or aluminum for humid areas to prevent corrosion.

- Durability Needs: If the valve will be installed in a high-traffic area, opt for more durable materials like steel.

Step 4: Deciding on Valve Type

- Manual vs. Automated: Decide between manual or automated valves. Automated valves offer more precise control and can be integrated with smart HVAC systems.

- Design Preferences: Consider the aesthetic aspect, especially if the valve will be visible. Select a style and finish that complements your space.

Step 5: Energy Efficiency Considerations

- Efficiency Ratings: Look for valves with good energy efficiency ratings to contribute to the overall energy conservation of your HVAC system.

Step 6: Seeking Professional Advice

- Consult Experts: If unsure, consult with an HVAC professional. They can provide valuable insights based on your specific circumstances and system requirements.

9. What is the installation process for HVAC air disc valves?

You can contact us or by following these steps, you also can successfully install an air disc valve in your HVAC system.

Step 1: Preparation

- Gather Necessary Tools: Ensure you have all the necessary tools, including a measuring tape, drill, screws, and the air disc valve itself.

- Safety First: Turn off the HVAC system and ensure safety precautions are taken to avoid any electrical hazards.

Step 2: Measuring and Marking

- Determine Location: Identify the location where the valve will be installed. This is typically on the ceiling or wall where the ductwork is accessible.

- Measure Accurately: Use a measuring tape to mark the exact dimensions of the valve on the installation surface.

Step 3: Cutting the Opening

- Cutting the Hole: If there isn’t an existing opening, use a saw or cutting tool to create a hole based on your measurements. The hole should match the size of the valve for a snug fit.

- Deburr Edges: Smooth any rough edges around the cut to prevent damage to the valve or injury during installation.

Step 4: Fitting the Valve

- Insert the Valve: Carefully place the air disc valve into the opening. Ensure that it sits flush against the surface and is aligned correctly.

- Securing the Valve: Use appropriate screws to secure the valve in place. Avoid overtightening, which could damage the valve or the surface.

Step 5: Adjusting the Valve

- Calibrate Airflow: Once installed, adjust the central disc of the valve to regulate the airflow according to your requirements.

- Test for Functionality: Turn the HVAC system back on and check if the air disc valve is functioning as expected, making further adjustments if necessary.

Step 6: Final Checks and Cleanup

- Inspect the Installation: Ensure that the valve is securely fitted and there are no gaps around the edges.

- Clean Up: Remove any debris or dust from the installation process and dispose of it properly.

10. Can I replace or upgrade existing valves in my system with air disc valves?

Replacing or upgrading to air disc valves can be a valuable investment in your HVAC system. With the right choice and proper installation, these valves can significantly enhance airflow control, contributing to the overall efficiency and comfort of your indoor environment.

Understanding the Feasibility of Replacement

- Compatibility Check: First, assess whether air disc valves are compatible with your current HVAC system. This includes checking duct size, type, and the existing valve mechanism.

- Benefit Analysis: Understand how air disc valves could benefit your system. They offer precise airflow control and can be more efficient in specific applications, like targeted air distribution.

Steps for Replacement or Upgrade

- Consult an HVAC Professional: Before making any changes, it’s advisable to consult with an HVAC expert. They can provide insights into the suitability and potential benefits of air disc valves for your system.

- Selecting the Right Valves: Choose air disc valves that match the size and airflow requirements of your space. Consider factors like material, design, and control type (manual or automated).

- Removing Old Valves: Safely remove the existing valves. This may involve some dismantling of ductwork, depending on how the current valves are installed.

- Installing Air Disc Valves: Follow the installation process for air disc valves, ensuring they are securely fitted and properly aligned with the ductwork.

- Testing the New Setup: Once installed, test the valves to ensure they are regulating airflow as expected. Make any necessary adjustments for optimal performance.

Considerations for a Successful Upgrade

- Ductwork Modification: In some cases, you may need to modify the ductwork to accommodate the new valves, especially if the size or type is significantly different.

- Cost vs. Benefit: Weigh the cost of replacement against the long-term benefits, such as improved energy efficiency and better airflow control.

- Aesthetic Impact: Consider how the new valves will look in your space. Air disc valves often come in various designs that can blend well with different interiors.

11. How do air disc valves affect airflow and distribution in a room or building?

Air disc valves are integral to the effective management of airflow and distribution within rooms and buildings as part of HVAC (Heating, Ventilation, and Air Conditioning) systems. Through their ability to control and direct airflow, they ensure efficient ventilation, uniform air distribution, and optimized HVAC system performance.

Examining the Influence of Air Disc Valves on Airflow and Distribution

1. Air Volume Control:

- Flow Regulation: Air disc valves are instrumental in controlling the volume of air that enters a space. They can be adjusted to increase or decrease airflow, allowing for precise management of room ventilation.

- Balancing Air Supply: By regulating airflow, these valves help maintain a balanced air supply, preventing issues like over-ventilation or insufficient air circulation.

2. Directional Airflow Management:

- Adjustable Angles: The design of air disc valves often includes adjustable features that allow the direction of the airflow to be altered. This capability is essential for directing air away from occupants to avoid drafts and ensuring air reaches all parts of the room.

- Customized Air Delivery: These adjustments enable customized airflow patterns, catering to the specific layout and usage needs of a room or building.

3. Enhancing Air Distribution Uniformity:

- Even Spread of Air: Properly configured air disc valves contribute to a more uniform distribution of air. This uniformity is vital for avoiding areas of stagnant air and ensuring a consistent indoor climate.

- Temperature and Humidity Consistency: Even air distribution aids in maintaining steady temperature and humidity levels throughout the space.

4. Impact on System Efficiency:

- Energy Usage Optimization: Efficient airflow regulation by air disc valves can lead to optimized energy usage. When air is distributed effectively, the HVAC system operates more efficiently, potentially reducing energy consumption and costs.

- System Longevity: Consistent and balanced airflow also means less strain on the HVAC system, contributing to its longevity and reducing the frequency of repairs and maintenance.

5. Supporting Indoor Air Quality:

- Mixing of Fresh and Recirculated Air: Air disc valves aid in the effective mixing of fresh external air with recirculated indoor air, crucial for diluting indoor pollutants and enhancing overall air quality.

- Reducing Contaminants: Efficient air distribution through these valves helps in minimizing concentrations of contaminants, contributing to a healthier indoor environment.

12. What maintenance is required for HVAC air disc valves?

Routine cleaning, inspection, lubrication, and adjustments are necessary to ensure these components function optimally. Proper upkeep not only extends their lifespan but also ensures they function efficiently, contributing to the overall effectiveness of the HVAC system.

Maintenance Strategies for HVAC Air Disc Valves

1. Routine Cleaning:

- Dust and Debris Removal: Accumulated dust and debris can hinder the performance of air disc valves. Regular cleaning, which involves wiping the surfaces and clearing any obstructions, is essential.

- Cleaning Frequency: The frequency of cleaning depends on the environment. In dust-prone areas, more frequent cleaning may be necessary.

2. Inspection for Damage or Wear:

- Visual Checks: Periodically inspect air disc valves for any signs of damage, wear, or corrosion. Look for issues like bent blades, cracks, or rust, which can affect their functionality.

- Prompt Repairs: Address any identified damage immediately to prevent further deterioration and to maintain efficient airflow.

3. Lubrication of Moving Parts:

- Smooth Operation: If the air disc valves have adjustable features or moving parts, ensure these are lubricated as needed. This step is crucial for maintaining smooth operation and preventing stiffness or squeaking sounds.

- Use Appropriate Lubricants: Select a lubricant that is suitable for the material of the valve and the environmental conditions it is exposed to.

4. Ensuring Proper Alignment and Fit:

- Check Alignment: Regularly ensure that the air disc valves are properly aligned and fitted. Misalignment can lead to airflow issues and reduced system efficiency.

- Seal Integrity: Verify that the seal between the valve and ductwork is intact. Any gaps can lead to air leakage, impacting the effectiveness of the HVAC system.

5. Monitoring Airflow Performance:

- Airflow Assessment: Occasionally assess the airflow from the valves. Reduced airflow could indicate blockages or damage that needs addressing.

- Adjustment and Balancing: If necessary, adjust the valves to ensure balanced air distribution throughout the space.

6. Professional HVAC System Check-Ups:

- Regular HVAC Maintenance: Include the inspection and maintenance of air disc valves as part of broader HVAC system maintenance performed by professionals.

- Expert Evaluation: HVAC technicians can provide a more thorough evaluation of the valves, including checking for any underlying issues that might not be immediately apparent.

13. How long do air disc valves typically last?

The lifespan of air disc valves in HVAC systems can vary widely based on material quality, environmental conditions, usage patterns, and maintenance practices. On average, these components can serve effectively for several years, but proactive care and regular check-ups are key to maximizing their lifespan.

Assessing the Typical Lifespan of Air Disc Valves

1. Average Durability:

- General Lifespan: On average, air disc valves can last anywhere from 5 to 15 years. However, this range can vary based on several factors, including material quality, usage conditions, and maintenance frequency.

2. Material and Construction Impact:

- Material Quality: Air disc valves are commonly made from materials like aluminum, steel, or plastic. The durability of these materials significantly affects the valve’s lifespan. For instance, metal valves often last longer than plastic ones due to their sturdier nature.

- Construction and Design: The design and build quality also play a crucial role. Well-designed valves with robust construction are likely to have a longer lifespan.

3. Environmental Influences:

- Exposure to Elements: Valves installed in areas with high humidity, fluctuating temperatures, or corrosive environments may have a reduced lifespan.

- Indoor vs. Outdoor Use: Valves used outdoors or in industrial settings are exposed to harsher conditions compared to those used in typical indoor environments, which can impact their durability.

4. Usage and Operational Factors:

- Frequency of Use: The more frequently the valves are adjusted or the higher the airflow they handle, the more wear they are likely to experience.

- Mechanical Stress: Valves subjected to constant mechanical stress or high-pressure conditions may have a shortened lifespan.

5. Maintenance and Care:

- Regular Maintenance: Regular cleaning and maintenance can significantly prolong the life of air disc valves. Neglect, on the other hand, can lead to early failures.

- Professional Inspections: Periodic inspections by HVAC professionals can help identify and address issues that may affect the valves’ longevity.

6. Signs of Aging:

- Wear Indicators: Common signs that an air disc valve may need replacing include reduced airflow efficiency, visible damage, or increased operational noise.

14. Are there any common issues or problems associated with air disc valves?

While air disc valves are generally reliable components of HVAC systems, Like any mechanical device, they can encounter specific issues or problems over time, such as airflow obstruction, mechanical wear and tear, corrosion, noise, uneven airflow, and air leaks.

Key Problems Frequently Encountered with Air Disc Valves

1. Airflow Obstruction:

- Dust and Debris Accumulation: One of the most common issues is the buildup of dust and debris, which can obstruct airflow, leading to reduced efficiency and performance.

- Regular Cleaning: To prevent this, routine cleaning and maintenance of the valves are necessary.

2. Mechanical Wear and Tear:

- Operational Strain: Over time, the mechanical components of air disc valves, such as the adjustment levers or internal mechanisms, can experience wear and tear, especially in valves that are frequently adjusted.

- Lubrication and Checks: Periodic lubrication and checks can mitigate these issues, ensuring smooth operation.

3. Corrosion and Material Degradation:

- Environmental Impact: In environments with high humidity or corrosive elements, valves, especially those made of susceptible materials, can undergo corrosion or material degradation.

- Material Selection and Protection: Choosing valves made from corrosion-resistant materials or ensuring they have protective coatings can prolong their lifespan.

4. Noise Issues:

- Operational Noise: Sometimes, air disc valves can become noisy during operation. This issue is typically due to mechanical faults or airflow obstructions.

- Inspection and Repair: Inspecting and repairing any mechanical faults or removing blockages can resolve noise issues.

5. Inconsistent Airflow Distribution:

- Unbalanced Air Delivery: Another common problem is uneven or inconsistent airflow distribution, which can result from improper installation, incorrect sizing, or mechanical issues within the valve.

- System Assessment and Adjustment: Ensuring correct installation and periodically assessing the system can help maintain balanced airflow.

6. Leakage and Seal Integrity:

- Air Leaks: Air leakage around the valve can occur, especially if the seal between the valve and ductwork is compromised.

- Seal Inspection: Regularly inspecting and maintaining the integrity of the seals is crucial to prevent air leaks.

15. Can air disc valves be integrated with automated or smart HVAC systems?

Integrating air disc valves with automated and smart HVAC systems is not only feasible but also brings significant benefits in terms of operational efficiency, energy management, and user convenience. Such integration marks a step forward in HVAC technology, aligning traditional ventilation components with the advancements of smart building systems.

- Compatibility with Automation

- Adaptable Design: Modern air disc valves are designed to be compatible with automated systems, allowing for seamless integration.

- Motorized Controls: Some valves come equipped with motorized mechanisms that can be connected to automated systems for precise airflow control.

- Smart System Integration

- Smart Controls: Air disc valves can be linked to smart HVAC systems, enabling remote control and adjustments through smart devices.

- Sensor-Based Operation: When integrated with smart systems, these valves can automatically adjust based on real-time data from sensors, like temperature and occupancy.

- Enhanced Efficiency and Comfort

- Optimized Performance: Integration with smart systems allows for more efficient operation of the HVAC system, ensuring optimal comfort and energy savings.

- Responsive Adjustments: Smart systems can dynamically adjust the valves for changing environmental conditions, providing consistent comfort.

- Customization and Flexibility

- Tailored Airflow: Users can customize airflow settings via smart interfaces, tailoring the indoor climate to personal preferences or specific room requirements.

- Zoning Capabilities: In smart HVAC systems, air disc valves can be controlled independently, enhancing zoning capabilities for different areas of a building.

- Ease of Installation and Retrofitting

- Retrofit Compatibility: Many modern air disc valves are designed to be retrofitted into existing systems, making them suitable for upgrades to smart technology.

- Professional Installation Recommended: For optimal integration, professional installation is recommended to ensure compatibility and efficiency.

16. How do noise levels of air disc valves compare to other valve types?

Air disc valves generally offer a quieter operation compared to some other valve types, thanks to their design and adjustability. While noise levels are an important factor, it’s essential to balance acoustic performance with other functional requirements of the HVAC system to achieve the desired environment.

Air Disc Valves and Noise Levels

- Design Efficiency: Air disc valves are designed to minimize noise. Their structure allows for a smoother airflow, which typically results in lower noise levels.

- Adjustability and Noise: The ability to precisely control the opening of air disc valves helps in reducing noise. Proper adjustment can minimize turbulence and, consequently, the sound generated.

Comparison with Other Valve Types

- Butterfly Valves

- Potential for Noise: Butterfly valves can produce more noise, especially at higher air speeds, due to the turbulence created by their flat, pivoting design.

- Application Matters: In large ducts where higher air volumes are managed, the noise difference can be more pronounced.

- Gate Valves

- Low Noise Operation: When fully open, gate valves generally produce less noise as they offer minimal resistance to airflow. However, they are not typically used for regulating airflow, limiting their comparability.

- Globe Valves

- Higher Noise Levels: Due to their design, which involves a plug moving into and out of a seat, globe valves can create more noise, especially when partially closed, as they cause significant airflow turbulence.

Factors Influencing Noise in Valves

- Air Speed: Higher air speeds through any valve type can increase noise levels due to increased turbulence.

- Installation Quality: Proper installation is crucial for minimizing noise. Poorly installed valves, regardless of type, can contribute to increased noise levels.

- Maintenance: Regular maintenance can help in keeping noise levels low. Worn or damaged parts in valves can lead to increased noise.

Mitigating Noise in HVAC Systems

- Consider Acoustic Lining: For ductwork prone to noise, consider using acoustic lining materials.

- Professional Assessment: If noise is a concern, a professional assessment can help in choosing the right valve type and design for your specific needs.

17. Are there any particular environments or conditions where air disc valves perform best?

Air disc valves excel in environments where controlled, moderate, and quiet airflow is required. Their design and functionality make them particularly suitable for residential and office spaces, energy-efficient buildings, and areas with specific ventilation needs.

1. Controlled Airflow Needs

- Precise Ventilation Areas: Air disc valves are ideal in spaces where precise airflow control is necessary, such as in laboratories, hospitals, or server rooms, where maintaining specific air conditions is crucial.

2. Residential and Commercial Spaces

- Home and Office Use: Their ability to provide adjustable and efficient airflow makes them well-suited for residential homes and office buildings, enhancing comfort and air quality in these environments.

3. Humid or Damp Conditions

- Corrosion Resistance: In areas with high humidity or dampness, air disc valves made from corrosion-resistant materials like stainless steel or certain plastics perform effectively, maintaining their functionality without degrading.

4. Spaces with Noise Sensitivity

- Quiet Operation: Their design, which typically produces less noise compared to other types of valves, makes air disc valves suitable for environments where noise levels are a concern, such as libraries or recording studios.

5. Retrofitting and Upgrades

- Ease of Installation: Due to their compact size and flexible installation options, air disc valves are beneficial in retrofitting projects or system upgrades, especially where space is limited or in older buildings.

6. Energy-Efficient Buildings

- Enhanced HVAC Efficiency: In buildings where energy efficiency is a priority, these valves contribute effectively by providing precise airflow control, reducing the energy load on HVAC systems.

7. Areas Requiring Frequent Adjustment

- User Control: In spaces where airflow needs to change frequently, such as conference rooms or function halls, the adjustability of air disc valves allows for quick adaptation to different requirements.

Considerations for Optimal Performance

- Proper Sizing and Placement: Ensure that the valves are correctly sized and placed for the specific environment to maximize their efficiency.

- Regular Maintenance: Keep the valves well-maintained to ensure they continue to perform optimally in the chosen environment.

18. What are the cost implications of choosing air disc valves over other options?

Choosing air disc valves involves weighing the initial higher costs against long-term savings and benefits. Their energy efficiency, low maintenance, and durability make them a cost-effective option over time, particularly in settings where precise airflow control is essential.

1. Initial Purchase Price

- Comparative Costs: Air disc valves, depending on their material and design, may have a slightly higher initial purchase price compared to basic valve types like simple butterfly or gate valves.

- Material Influence: The cost can vary significantly based on the material – metal valves tend to be more expensive than plastic ones.

2. Installation Costs

- Ease of Installation: Air disc valves are generally straightforward to install, potentially reducing labor costs, especially in retrofitting scenarios.

- Compatibility Considerations: If your system requires significant modifications to accommodate these valves, installation costs could increase.

3. Operational Efficiency and Energy Savings

- Long-Term Savings: While the upfront cost might be higher, air disc valves can lead to energy savings due to their precise airflow control, reducing operational costs over time.

- Reduced HVAC Load: Improved efficiency can also lower wear and tear on the HVAC system, potentially saving on maintenance and repair costs.

4. Maintenance and Durability

- Low Maintenance Requirements: These valves typically require less maintenance, which can lead to cost savings in the long run.

- Longevity: Durable materials and design mean air disc valves may have a longer lifespan, reducing the need for replacements.

5. Customization Costs

- Standard vs. Custom Models: Customized air disc valves, whether in size, material, or design, will be more expensive than standard models.

- Aesthetic Modifications: If aesthetic customization is required, it may also add to the cost.

6. Comparing with Other Valve Types

- Cost vs. Performance: More sophisticated valve types like automated or sensor-equipped models may offer additional features but at a higher cost.

- Application-Specific Choices: The cost-effectiveness of air disc valves becomes more apparent in applications requiring precise airflow control.

19. Where can I purchase HVAC air disc valves, and what should I look for in a supplier?

Purchasing HVAC air disc valves can be done through various channels, including HVAC specialty stores, online retailers, direct from manufacturers, or local hardware stores. When selecting a supplier, focus on their range of products, commitment to quality, level of expertise, and the value-added services they offer.

Finding the Right Places to Purchase HVAC Air Disc Valves

1. HVAC Specialty Stores:

- Dedicated Retailers: Specialty stores focusing on HVAC equipment often offer a wide range of air disc valves. They can provide expert advice and a variety of options suited to different needs.

- Hands-On Experience: Visiting these stores allows you to see and compare different models firsthand.

2. Online HVAC Retailers and Marketplaces:

- The Convenience of Online Shopping: Online retailers and marketplaces like Amazon, eBay, or specific HVAC e-commerce sites are convenient options, offering a broad selection of air disc valves.

- Customer Reviews: Online platforms provide the benefit of customer reviews, which can offer insights into product performance and reliability.

3. Direct from Manufacturers:

- Brand-Specific Products: Purchasing directly from manufacturers is a reliable way to get specific brands or models. It’s particularly useful when you need a replacement that matches existing system components.

- Warranty and Support: Manufacturers often provide warranties and customer support, ensuring you get assistance if needed.

4. Local Hardware Stores:

- Accessibility: Hardware stores may carry a range of air disc valves and are easily accessible for quick purchases.

- Limited Variety: Be aware that their selection might be more limited compared to specialty stores or online platforms.

What to Look for in a Supplier

1. Product Range and Availability:

- Wide Selection: Choose suppliers that offer a wide range of air disc valves, catering to different system types and specifications.

- Stock Availability: Ensure the supplier regularly stocks the valves or can quickly order them.

2. Quality and Compliance:

- Certified Products: Look for suppliers that offer products compliant with industry standards and certifications, ensuring quality and safety.

- Reputable Brands: Prefer suppliers that stock valves from reputable manufacturers known for their quality.

3. Expertise and Support:

- Knowledgeable Staff: A good supplier should have knowledgeable staff who can offer advice on the best type of valve for your specific HVAC system.

- After-Sale Support: Check if the supplier provides after-sale support, including installation guidance and troubleshooting.

4. Price and Warranty:

- Competitive Pricing: Compare prices from different suppliers to ensure you are getting a good deal.

- Warranty Offers: Opt for suppliers that provide warranties on their products, adding an extra layer of security to your purchase.

20. Is there any warranty or after-sales support offered with air disc valves?

Most air disc valves come with a manufacturer’s warranty. The duration can vary, typically ranging from one to several years, depending on the brand and manufacturer. Warranties usually cover defects in materials and workmanship. It’s important to read the warranty terms to understand what is and isn’t covered.

After-Sales Support That Stands Out – We believe in supporting our customers long after the sale. Our commitment to your satisfaction doesn’t end at the checkout:

- Comprehensive Warranty: Our HVAC floor grilles come with an extensive warranty, assuring you of our confidence in their quality and longevity.

- Responsive Customer Service: Have questions? Need assistance? Our dedicated customer service team is just a call or email away, ready to assist you with any concerns or inquiries.

- Expert Guidance: Whether it’s installation advice or maintenance tips, our experts are here to provide you with the support you need to get the most out of your purchase.

Need High-quality HVAC Grilles and Diffusers? Shoot us a message, and I’ll be happy to assist you in picking the right grilles or diffusers for your needs.