Basic Introduction of HVAC Access Panels

Welcome to AIREVERPEAK, where we specialize in the production of HVAC Access Panels, a crucial component for air conditioning, ventilation, and purification systems. Our panels are recognized for their durability and quality, as evidenced by our extensive certifications, including CE, UL, and ISO standards. As an AAA level enterprise and a leading brand in China’s refrigeration industry, we offer a range of access panels tailored to various needs. Our commitment lies in providing high-quality materials, customizable options, and efficient delivery – all at competitive prices. Trust AIREVERPEAK for reliable, innovative, and eco-friendly HVAC solutions.

Customer-Centric Offerings:

- High-Quality Materials: Durable access panels built to withstand harsh conditions.

- Customization: Tailored solutions in size, color, and features to meet unique requirements.

- Efficient Delivery & Competitive Pricing: Quick, reliable service with attractive pricing for B2B customers.

Commitment to Excellence:

- Expert Support: Access to technical experts for optimal product selection and installation advice.

- Safety & Compliance: Adherence to industry standards and regulations.

- Warranties & Guarantees: Assurance of product quality and performance.

Innovation & Sustainability:

- Eco-Friendly Options: Emphasis on sustainable and energy-efficient products.

- Online Ease & Bulk Orders: Streamlined, secure online ordering and inventory management.

- Customer Trust: Built on positive reviews, educational resources, and a strong reputation.

Basic styles and sizes of HVAC Access Panels

If you want to know more, please click below:

- HVAC Linear Slot Diffusers – The Ultimate Guide

- HVAC Egg Crate Diffuser – The Ultimate Guide

- HVAC Jet Nozzle Diffuser – The Ultimate Guide

- HVAC Linear Bar Grilles – The Ultimate Guide

- HVAC Air Swirl Diffusers – The Ultimate Guide

- HVAC Round Ceiling Diffusers – The Ultimate Guide

- Round Ceiling Diffusers – The Ultimate Guide

- HVAC Return Air Grille – The Ultimate Guide

- Exhaust Air Louver – The Ultimate Guide

- HVAC Registers – The Ultimate Guide

HVAC Access Panel – The Ultimate Guide

1. What are access panels in HVAC systems, and why are they important?

Access panels in HVAC systems are essentially doors or portals that provide technicians with quick and easy access to various parts of the system, such as ducts, vents, and other components. Their design is not just about functionality; it also embodies a blend of aesthetics and practicality.

Importance of Access Panels

- Maintenance and Repairs:

- They provide a convenient entry point for regular maintenance.

- Essential for quick repairs, reducing downtime.

- Safety and Compliance:

- Help in adhering to safety standards and building codes.

- Facilitate inspections to ensure the system is running safely and efficiently.

- System Efficiency:

- Regular access for cleaning and maintenance ensures optimal system performance.

- Helps in identifying and fixing issues before they escalate, saving energy and costs.

- Longevity of the HVAC System:

- By enabling easy maintenance, they extend the lifespan of the system.

- Prevents major breakdowns by allowing for timely interventions.

2. What is the difference between an access door and an access panel?

Access Doors

- Definition:

- An access door is a hinged or sliding door that provides entry into a larger space.

- Typically larger than access panels.

- Usage:

- Commonly used for entering larger areas such as attics, crawl spaces, or service areas.

- Suitable for spaces that require regular human entry.

- Construction:

- Made from various materials, including metal, wood, or plastic.

- Often includes locks or latches for security.

Access Panels

- Definition:

- An access panel is a smaller, often removable, panel.

- It provides access to a confined space or utility box.

- Usage:

- Ideal for accessing electrical, plumbing, or HVAC components.

- Used in walls, ceilings, or floors for minor maintenance tasks.

- Construction:

- Generally smaller and more discreet than access doors.

- Can be screw-fixed, snap-locked, or magnetically sealed.

Key Differences

- Size and Function:

- Access doors are larger and meant for areas requiring human entry.

- Access panels are smaller, and designed for quick access to systems or utilities.

- Location and Installation:

- Access doors are installed in more accessible areas like walls or ceilings.

- Access panels are often integrated into less visible areas for specific system access.

- Purpose and Frequency of Use:

- Access doors are used for spaces that need regular, direct human access.

- Access panels are more for occasional maintenance and inspections.

3. How are access panels installed?

Let’s check one professional video:

Steps for Installing Access Panels

- Selection of the Right Panel:

- Choose a panel that fits the size and material of the wall, ceiling, or floor where it will be installed.

- Consider the panel’s load-bearing capacity and whether it needs to be fire-rated, insulated, or water-resistant.

- Preparation of the Installation Site:

- Locate the area where the panel will be installed. Ensure it’s easily accessible and provides adequate space for maintenance tasks.

- Use a stud finder to avoid cutting into any structural supports or wiring.

- Marking and Cutting the Opening:

- Measure and mark the dimensions of the panel on the installation surface.

- Cut the opening using appropriate tools like a drywall saw or a jigsaw, ensuring the cut is clean and precise.

- Fitting the Panel:

- Place the panel into the opening to check the fit. It should sit flush with the surface without forcing it.

- For panels with frames, secure the frame into the opening first.

- Securing the Panel:

- Use screws, adhesives, or clips provided with the panel to secure it in place.

- Ensure that the panel is level and properly aligned.

- Finishing Touches:

- Apply caulk or sealant around the edges of the panel if required, especially in areas exposed to moisture.

- If necessary, paint or finish the panel to match the surrounding area.

Important Considerations

- Safety First: Always turn off power or water supply when working near electrical or plumbing systems.

- Tools and Materials: Have all necessary tools and materials ready before beginning, such as measuring tape, a saw, screws, and a drill.

- Follow Manufacturer Instructions: Different types of panels may have specific installation requirements, so it’s important to follow the manufacturer’s instructions.

4. How do I choose the right size and type of access panel for my HVAC system?

Understanding Your HVAC System’s Requirements

- Assess the Location and Purpose:

- Identify where the access panel will be installed (e.g., wall, ceiling, or ductwork).

- Determine the purpose: Is it for regular maintenance, inspections, or emergency access?

- Evaluate the Space Available:

- Measure the area where you plan to install the panel.

- Ensure there’s enough room around the panel for easy opening and access.

Choosing the Right Size

- Measure Accurately:

- Use a tape measure to determine the dimensions of the opening required.

- Consider any obstructions or structural elements that might impact the size.

- Factor in Clearance:

- Ensure the panel is large enough for tools and hands to comfortably fit through.

- Allow extra space for components that may need to be removed or replaced.

Selecting the Appropriate Type

- Material Considerations:

- Panels are available in materials like metal, plastic, or wood.

- Choose a material that suits the environment (e.g., moisture-resistant for damp areas).

- Insulation and Fire Rating:

- If energy efficiency is a concern, consider insulated panels.

- In certain areas, a fire-rated panel may be required for safety.

- Locking Mechanism:

- Decide if you need a panel with a lock for additional security.

- Some panels come with simple screw closures, while others have keyed locks.

Additional Features to Consider

- Aesthetic Compatibility: Select a panel that blends with the surrounding area, especially in visible locations.

- Ease of Installation: Consider how easy the panel is to install. Some may require professional installation, while others can be a DIY project.

- Maintenance Needs: Think about long-term maintenance and choose a panel that is easy to clean and durable.

5. What materials are HVAC access panels typically made from?

HVAC access panels are made from various materials, including metal, plastic, wood, and gypsum. The choice of material depends on factors like environmental conditions, security requirements, aesthetic considerations, and budget. Each offers different benefits and suitability for specific environments and purposes.

Common Materials for HVAC Access Panels

- Metal:

- Types: Steel and aluminum are the most common.

- Advantages: Durable, strong, and often fire-resistant. Ideal for high-security areas.

- Usage: Widely used in commercial and industrial settings.

- Plastic:

- Types: High-impact plastics like ABS or PVC.

- Advantages: Lightweight, corrosion-resistant, and often more affordable. Easier to install.

- Usage: Suitable for residential properties or where corrosion is a concern.

- Wood:

- Types: Plywood or medium-density fiberboard (MDF) are common.

- Advantages: Aesthetically pleasing and can be easily painted or stained to match the decor.

- Usage: Often used in residential settings for a more natural look.

- Gypsum:

- Types: Panels made with a gypsum core and covered in paper or fiberglass.

- Advantages: Easily blend with drywall, making it visually unobtrusive.

- Usage: Ideal for indoor applications where aesthetics are important.

Considerations When Choosing Material

- Environment:

- Consider the location of the panel. Moist or outdoor environments may require corrosion-resistant materials like plastic or certain metals.

- Security and Safety:

- In areas where security is a concern, metal panels are preferable.

- Fire-rated materials are important in certain building zones.

- Aesthetics:

- For panels that will be visible, consider materials that can blend with or complement the surrounding area.

- Budget and Longevity:

- Metal panels are typically more expensive but offer greater durability.

- Plastic and wood are cost-effective options but may have a shorter lifespan in certain conditions.

6. Are there fire-rated access panels for HVAC systems?

Yes, fire-rated access panels are available and are an important feature in many HVAC systems, especially in buildings where fire safety is a critical concern.

Understanding Fire-Rated Access Panels

- Purpose:

- Designed to withstand fire for a specified period, typically ranging from 30 minutes to 2 hours.

- Helps to prevent the spread of fire and smoke through ductwork and other openings.

- Construction:

- Made from materials that are resistant to high temperatures, such as steel.

- Often include insulation materials like mineral wool to enhance fire resistance.

Importance in HVAC Systems

- Safety Regulations:

- Fire-rated panels are often required by building codes, especially in commercial or multi-story residential buildings.

- They are crucial in areas that are more susceptible to fire hazards.

- Protecting Key Areas:

- Installed in critical locations to protect essential components of the HVAC system.

- Helps in safeguarding the structural integrity of a building during a fire.

Choosing Fire-Rated Panels

- Rating Requirements:

- Check the fire rating needed for your specific application, which is usually determined by local building codes.

- Ratings are generally given in terms of time (e.g., 1-hour fire rating).

- Size and Fit:

- Ensure the panel fits the designated space correctly.

- Proper installation is crucial for the panel to perform effectively.

- Additional Features:

- Some fire-rated panels come with additional features like smoke seals.

- Consider panels with locks for added security.

Fire-rated access panels are a vital component in HVAC systems for enhancing fire safety. They are specially designed to resist high temperatures and prevent the spread of fire and smoke. When selecting a fire-rated panel, it’s important to consider the specific fire-rating requirements, ensure proper sizing and installation, and look for any additional features that might be beneficial.

7. How do access panels contribute to the efficiency of HVAC systems?

Access panels are more than just a structural feature; they are integral to the efficient operation of HVAC systems. By facilitating easier maintenance, inspections, and repairs, they help ensure that the system runs smoothly, uses energy effectively, and has a longer operational life. Access panels impact everything from maintenance to system performance.

Key Contributions of Access Panels to HVAC Efficiency

- Ease of Maintenance and Repairs:

- Provide direct access to internal components of the HVAC system, like ducts, filters, and coils.

- Simplifies routine maintenance tasks, such as cleaning and replacing filters, which are essential for efficient system operation.

- Improving System Longevity:

- Regular maintenance made easier by access panels can extend the life of the HVAC system.

- Prevents the build-up of debris and dust, which can cause wear and tear if left unchecked.

- Enhancing System Performance:

- Ensures that components are easily accessible for inspection and repairs, minimizing downtime.

- A well-maintained system, accessible through these panels, operates more efficiently, reducing energy consumption.

- Facilitating Inspections:

- Access panels allow for quick inspections of the HVAC system.

- Early detection of issues through regular inspections can prevent more significant problems and inefficiencies.

- Compliance with Regulations:

- In many cases, having proper access panels is a requirement for building codes and safety standards.

- They ensure that the HVAC system is up to date with regulatory standards, often linked with efficiency requirements.

8. What are the installation requirements for HVAC access panels?

Installing HVAC access panels requires careful consideration of size, location, and installation methods to ensure safety and functionality. Adhering to these requirements is crucial for safety, accessibility, and the overall efficiency of the HVAC system.

Key Installation Requirements for HVAC Access Panels

- Correct Sizing:

- Measure the space where the panel will be installed to ensure a proper fit.

- The size should allow for easy access to HVAC components for maintenance and repairs.

- Appropriate Location:

- Install panels in places that are easily accessible for maintenance staff.

- Avoid locations where the panel could be obstructed by furniture or other barriers.

- Safe Installation Practices:

- Turn off power to the area where the panel will be installed to prevent accidents.

- Use proper tools and safety equipment during the installation.

- Securing the Panel:

- Fasten the panel securely to prevent air leaks, which can reduce HVAC efficiency.

- Use screws or other recommended fasteners as per the panel’s design.

- Sealing and Insulation:

- Apply sealant around the edges of the panel to prevent air leakage and energy loss.

- Consider insulated panels to maintain energy efficiency, especially in temperature-sensitive areas.

- Compliance with Building Codes:

- Ensure the installation meets local building and safety codes.

- This may include using fire-rated panels in certain areas.

- Consideration for Aesthetics:

- Choose panels that blend with the surrounding area, especially in visible locations.

- Finish or paint the panel as needed to match the interior décor.

9. Can access panels be customized for specific HVAC applications?

Certainly! Customization of access panels for specific HVAC applications is not only possible but often necessary to meet the unique requirements of different HVAC systems. This customization allows for tailored solutions that address the specific needs of a given installation.

Customization of HVAC Access Panels

- Size Customization:

- Access panels can be tailored to fit unique dimensions, especially in spaces where standard sizes don’t fit.

- Custom sizing is crucial for ensuring a snug fit and maintaining the efficiency of the HVAC system.

- Material Selection:

- Panels can be made from a variety of materials, such as metal, plastic, or wood, depending on environmental factors and aesthetic preferences.

- Material choice can impact the panel’s durability, insulation properties, and resistance to elements.

- Design Features:

- Features like insulation, fire resistance, and soundproofing can be incorporated based on the application’s requirements.

- Locking mechanisms can be customized for added security or ease of access.

- Aesthetic Customization:

- Panels can be designed to blend seamlessly with the surrounding environment, including color matching and finishing.

- This is particularly important in areas where visual appearance is a priority.

- Special Functionalities:

- For specific applications, additional features like airtight seals, thermal barriers, or dampers can be integrated.

- Such functionalities are important in maintaining the overall efficiency and safety of the HVAC system.

Importance of Customization

- Enhanced Efficiency: Custom panels ensure proper fit and functionality, directly impacting the efficiency of the HVAC system.

- Specific Needs Addressed: Tailored solutions cater to the unique needs of different environments, whether it’s a residential, commercial, or industrial setting.

- Regulatory Compliance: Custom panels can help in meeting specific building codes and safety standards, which may vary by location.

Customization of access panels is a valuable option for specific HVAC applications. It allows for the creation of panels that perfectly fit the unique requirements of different systems, whether in terms of size, material, design, or functionality. Such tailored solutions not only enhance the efficiency and performance of the HVAC system but also ensure that they align with aesthetic and regulatory requirements.

10. How do I maintain and clean HVAC access panels?

Regular maintenance and cleaning involves inspecting, adjusting, and cleaning the panels and their surrounding areas. Regular maintenance ensures that the panels remain functional and prolong their lifespan.

Routine Maintenance of HVAC Access Panels

- Regular Inspection:

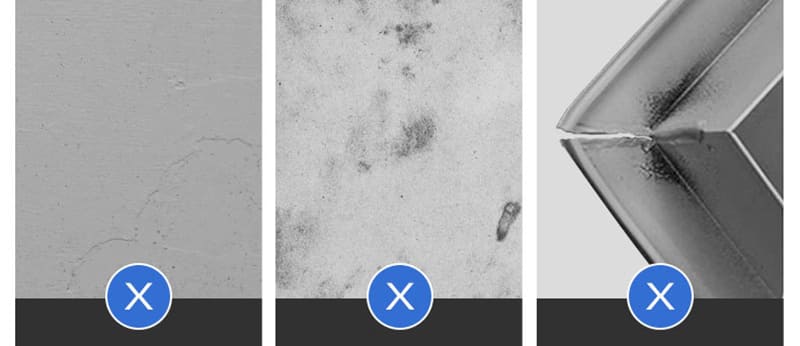

- Periodically check the panels for any signs of damage, such as dents, rust, or loose hinges.

- Inspect the seals and gaskets to ensure they are intact and provide a proper seal.

- Tightening and Adjusting:

- Tighten any loose screws or fasteners to ensure the panel is securely attached.

- Adjust hinges or latches if the panel doesn’t close properly.

- Checking for Obstructions:

- Ensure that nothing is blocking the panel, which could hinder access to HVAC components.

- Keep the area around the panel clear for easy maintenance access.

Cleaning Process

- Dusting and Wiping:

- Start by dusting the panel to remove surface dirt and debris.

- Use a soft cloth and mild detergent to gently wipe the panel. Avoid abrasive cleaners that can damage the surface.

- Cleaning the Surrounding Area:

- Clean the area around the access panel to prevent dust from entering the HVAC system.

- This includes vacuuming or wiping down adjacent walls, floors, or ceilings.

- Handling Different Materials:

- For metal panels, check for signs of corrosion and clean accordingly.

- Wooden panels might require specific cleaning agents to avoid damage.

- Dry Thoroughly:

- Ensure the panel and surrounding area are completely dry after cleaning to prevent moisture buildup.

Additional Tips

- Gentle Handling: Be careful when opening and closing the panels to prevent damage.

- Avoid Water Intrusion: When cleaning, avoid letting water seep into the HVAC system.

- Follow Manufacturer Guidelines: Refer to the manufacturer’s instructions for specific cleaning and maintenance advice.

11. What are the cost implications of installing high-quality access panels in HVAC systems?

Installing high-quality access panels in HVAC systems involves certain cost implications that are important to consider. While initial expenses may be higher, the long-term benefits often outweigh these costs. Here’s a breakdown of the key factors:

Initial Investment in High-Quality Access Panels

- Higher Material Costs:

- Quality panels are often made of more durable materials, which can be more expensive.

- Features like insulation, fire resistance, or special locking mechanisms also add to the cost.

- Installation Expenses:

- Professional installation may be required, especially for specialized panels.

- Costs may vary depending on the complexity of the installation.

Long-Term Cost Savings

- Reduced Maintenance Costs:

- Durable panels are less likely to need repairs or replacements, reducing long-term maintenance expenses.

- Easier access to HVAC maintenance can lead to lower service costs.

- Energy Efficiency:

- Well-insulated and properly sealed panels can improve the efficiency of the HVAC system, leading to lower energy bills.

- This can result in significant savings over the life of the system.

- Enhanced System Longevity:

- Quality access panels can help protect HVAC components, potentially extending the system’s lifespan.

- This means savings on potential system replacements or major repairs.

Other Considerations

- Compliance and Safety:

- High-quality panels may better meet building codes and safety standards, reducing the risk of fines or compliance issues.

- Fire-rated panels, in particular, add a safety element that could prevent costly damages.

- Aesthetic Value:

- Premium panels often have better aesthetic integration into the building’s design, which might be important in certain settings.

While the initial cost of installing high-quality access panels in HVAC systems can be higher due to material and installation expenses, the long-term benefits often justify the investment. These benefits include reduced maintenance costs, improved energy efficiency, extended system longevity, compliance with safety standards, and potential aesthetic improvements. Carefully considering these factors will help in making an informed decision that balances upfront costs with long-term savings and benefits.

12. How do access panels in HVAC systems ensure safety and compliance with regulations?

Access panels in HVAC systems are fundamental for ensuring safety and regulatory compliance. They allow for essential maintenance and inspections, prevent unauthorized access, and contribute to fire safety. Compliance with building codes, energy efficiency regulations, and health standards is also facilitated by the proper installation and use of these panels.

Ensuring Safety Through Access Panels

- Facilitating Regular Maintenance and Inspections:

- Access panels provide easy entry points for technicians to perform routine checks and maintenance.

- Regular maintenance ensures the HVAC system operates safely, reducing risks of malfunctions that could lead to accidents.

- Preventing Unauthorized Access:

- Panels can be equipped with locks or secure fastening systems to prevent unauthorized access.

- This is especially important in commercial or industrial settings where tampering could lead to safety hazards.

- Fire Safety:

- Fire-rated access panels help contain fires and prevent the spread of flames and smoke.

- They are designed to withstand high temperatures, contributing to the overall fire safety strategy of a building.

Compliance with Regulations

- Building Codes and Standards:

- Proper access panels help ensure HVAC systems comply with local building codes and safety standards.

- Compliance often includes having access panels of specific sizes, materials, and fire ratings.

- Energy Efficiency Regulations:

- Well-sealed and insulated panels can improve the energy efficiency of HVAC systems.

- This helps in meeting regulations focused on energy conservation and sustainability.

- Health and Environmental Regulations:

- Access panels aid in maintaining indoor air quality by ensuring easy access for cleaning and replacing air filters.

- In certain industries, this is crucial for compliance with health and environmental regulations.

Key Considerations for Installation

- Appropriate Placement: Panels should be strategically placed for optimal safety and accessibility.

- Quality of Materials: Using high-quality materials for panels ensures durability and adherence to safety standards.

- Professional Installation: Proper installation by qualified personnel is crucial for ensuring that the panels function as intended and comply with all regulations.

13. What is the lifespan of a typical HVAC access panel?

The lifespan of a typical HVAC access panel can vary depending on several factors, including material quality, environmental conditions, and frequency of use.

Factors Affecting the Lifespan of HVAC Access Panels

- Material Quality:

- Panels made from high-quality, durable materials like heavy-duty steel or robust plastics tend to last longer.

- The resistance of the material to corrosion, moisture, and wear and tear plays a significant role.

- Environmental Conditions:

- Panels exposed to harsh conditions, such as extreme temperatures, humidity, or corrosive environments, may have a reduced lifespan.

- Indoor panels generally last longer than those installed outdoors.

- Usage Frequency:

- Panels that are opened and closed frequently, like those in high-maintenance areas, may wear out faster.

- Proper handling and use can prolong their functional life.

Typical Lifespan Estimates

- Metal Panels:

- High-quality metal panels, such as those made from stainless steel or aluminum, can last 15-20 years or more.

- Their lifespan can be extended with proper maintenance and if they are installed in a controlled environment.

- Plastic and Wood Panels:

- Panels made from plastics or wood may have a shorter lifespan, typically around 5-10 years.

- The quality of the material and protective coatings can influence their durability.

- Specialized Panels:

- Fire-rated or insulated panels might have specific lifespans based on their design and materials.

- Regular inspections and maintenance are crucial for ensuring their continued effectiveness.

Maintenance for Longevity

- Regular Cleaning: Keeping panels clean from dust and debris can prevent wear and extend their life.

- Inspection and Repairs: Periodically check for any signs of damage or wear and address issues promptly.

- Proper Installation: Ensuring that the panel is correctly installed can prevent undue stress and wear.

The lifespan of an HVAC access panel can vary greatly, but generally, high-quality metal panels can last upwards of 15-20 years, while those made from other materials like plastic or wood might last around 5-10 years.

Factors such as material quality, environmental conditions, and usage frequency play a crucial role in determining their longevity. Regular maintenance and proper installation are key to maximizing the lifespan of these panels.

14. Are there specific access panel solutions for outdoor HVAC units?

Absolutely, outdoor HVAC units require specific access panel solutions designed to withstand external environmental conditions. These specialized panels are made to endure factors like weather, temperature fluctuations, and potential exposure to moisture and debris.

Specialized Access Panels for Outdoor HVAC Units

- Weather-Resistant Materials:

- Choose panels made from materials that can withstand outdoor conditions, such as stainless steel or weather-resistant plastics.

- These materials are crucial for resisting corrosion, rust, and damage from UV exposure.

- Enhanced Durability:

- Panels designed for outdoor use are typically more robust to handle extreme weather conditions.

- They may have reinforced structures or added layers for extra strength.

- Sealing and Insulation:

- Good sealing is essential to prevent water and moisture ingress, which can damage the HVAC system.

- Insulated panels can be beneficial in maintaining temperature control within the unit.

- Locking Mechanisms for Security:

- Outdoor panels often come with secure locking systems to prevent unauthorized access or tampering.

- This is particularly important in areas where security is a concern.

Considerations for Choosing Outdoor Panels

- Compatibility with HVAC Unit:

- Ensure the panel is suitable for the specific type of outdoor HVAC unit you have.

- Consider the size and layout of the unit for a proper fit.

- Maintenance and Access:

- The panel should allow easy access for regular maintenance and inspections.

- Consider panels that are easy to open and close, even in challenging outdoor conditions.

- Aesthetic Integration:

- While functionality is key, choosing a panel that blends with the outdoor environment can be important.

- Look for panels that match or complement the building’s exterior.

Access panel solutions for outdoor HVAC units are specifically designed to address the challenges of an outdoor environment. Key features to look for include weather-resistant materials, enhanced durability, proper sealing and insulation, and secure locking mechanisms. When selecting a panel, it’s important to consider factors such as compatibility with the HVAC unit, ease of maintenance, and aesthetic integration.

15. How do access panels assist in HVAC inspections and troubleshooting?

Access panels play a pivotal role in facilitating HVAC inspections and troubleshooting. They are designed to provide convenient and efficient access to various components of the HVAC system, crucial for regular checks and addressing issues.

Role of Access Panels in HVAC Inspections

- Easy Access to Components:

- Panels provide direct access to essential parts like ducts, coils, and filters.

- This accessibility is key for conducting thorough inspections without the need for extensive disassembly.

- Regular Maintenance Checks:

- Routine maintenance, such as filter replacement and cleaning, is made simpler.

- Regular maintenance is crucial for identifying potential issues before they escalate.

Assisting in Troubleshooting

- Quick Identification of Issues:

- Access panels allow technicians to quickly reach and assess problem areas.

- This speeds up the process of diagnosing issues within the HVAC system.

- Facilitating Repairs and Adjustments:

- Technicians can easily perform repairs, adjustments, and replacements through these panels.

- Minimizes the downtime of the HVAC system during repairs.

Enhancing Overall System Efficiency

- Preventing Major Breakdowns:

- By enabling regular inspections, potential problems can be detected and addressed early.

- Prevents major breakdowns that can be costly and disruptive.

- Ensuring Optimal Performance:

- Regular access for cleaning and maintenance ensures the system operates at peak efficiency.

- Helps in maintaining the energy efficiency of the HVAC system.

Compliance and Safety

- Meeting Safety Standards:

- Access panels help ensure the system is compliant with safety and building codes.

- Regular inspections can identify safety hazards like leaks or electrical issues.

- Documentation and Record Keeping:

- Easier access allows for more detailed and regular documentation of the system’s condition.

- Important for regulatory compliance and maintenance records.

16. What are the latest innovations in HVAC access panel design?

The field of HVAC access panel design has seen several innovative developments in recent years, aimed at enhancing efficiency, security, and ease of use. These advancements reflect the evolving needs of modern HVAC systems and the buildings they serve.

Recent Innovations in HVAC Access Panel Design

- Smart Access Technologies:

- Integration of smart technology for remote monitoring and control.

- Panels can now be equipped with sensors and connected to building management systems for alerts and automated access.

- Improved Material Technology:

- Use of advanced materials that offer better durability, fire resistance, and insulation.

- Development of lighter yet stronger materials for ease of installation and maintenance.

- Enhanced Security Features:

- Advanced locking mechanisms, including keyless and electronic locks, enhance security.

- Some panels now feature tamper-proof designs to prevent unauthorized access.

- Eco-Friendly Designs:

- Focus on environmentally sustainable materials and production processes.

- Panels designed to improve the energy efficiency of HVAC systems, aiding in overall building sustainability.

- Customization and Aesthetics:

- Increased options for customization to fit specific HVAC system needs and aesthetic preferences.

- Panels are designed to blend seamlessly with various architectural styles.

- Ergonomic and User-Friendly Features:

- Designs that focus on ease of use, such as tool-free access and simple opening mechanisms.

- Consideration for ergonomic handling to reduce strain during maintenance work.

The Impact of These Innovations

- Improved Maintenance and Operation: The advancements in access panel design simplify maintenance tasks and enhance the overall operation of HVAC systems.

- Increased Safety and Compliance: Innovations in materials and design contribute to higher safety standards and easier compliance with building codes.

- Adaptability to Modern Needs: As buildings become more technologically integrated, these innovative access panels align with the evolving requirements of modern infrastructure.

The latest innovations in HVAC access panel design represent a significant leap forward in terms of technology, security, sustainability, and user-friendliness. Smart access features, improved materials, enhanced security, eco-friendly designs, customization options, and ergonomic considerations all contribute to making HVAC systems more efficient, safe, and easy to maintain. These advancements not only benefit the immediate operation of HVAC systems but also align with broader trends in building management and environmental sustainability.

17. Can HVAC access panels be retrofitted into existing systems?

Certainly, retrofitting HVAC access panels into existing systems is not only feasible but also quite common in building maintenance and upgrades. This process allows older HVAC systems to benefit from the improved functionality and efficiency that modern access panels provide.

Retrofitting Access Panels into Existing HVAC Systems

- Feasibility Assessment:

- Conduct a thorough assessment of the existing HVAC system to determine the best locations for access panels.

- Consider factors like ductwork layout, space constraints, and the most frequently accessed areas.

- Custom Sizing and Design:

- Since existing systems may have unique dimensions, custom-sized panels may be necessary.

- The design can be tailored to accommodate the specific needs and limitations of the system.

- Material Selection:

- Choose materials that complement the existing system and environment. For instance, corrosion-resistant materials for humid areas.

- The material should also align with any additional requirements, such as fire ratings or insulation.

- Installation Process:

- Professional installation is recommended to ensure that the panels are properly integrated into the existing system.

- The process typically involves cutting openings, fitting the panels, and ensuring they are securely fastened and sealed.

- Ensuring Compatibility:

- It’s important to ensure that the new panels do not interfere with the system’s functionality.

- Careful planning is required to avoid obstructing airflow or compromising the system’s integrity.

Benefits of Retrofitting

- Improved Access for Maintenance: Retrofitting access panels makes it easier to perform regular maintenance, leading to better system efficiency and longevity.

- Enhanced Safety and Compliance: Newer panels can help bring older systems up to current safety standards and building codes.

- Cost-Effective Upgrade: Retrofitting access panels can be a more cost-effective solution compared to overhauling the entire HVAC system.

Key Considerations

- Professional Assessment: Have a qualified HVAC professional assess the system to determine the best approach for retrofitting.

- Compliance with Standards: Ensure that the retrofitting process complies with local building codes and HVAC regulations.

- Minimal Disruption: Plan the retrofitting process to minimize disruption to the building’s occupants and operations.

Retrofitting HVAC access panels into existing systems is a practical and efficient way to upgrade older HVAC installations. It involves careful planning, custom sizing, and professional installation, but the benefits, including improved maintenance, safety, and system efficiency, make it a worthwhile endeavor. With the right approach, retrofitting can significantly enhance the functionality and lifespan of an existing HVAC system.

18. How do HVAC access panels affect air quality and ventilation?

HVAC access panels significantly impact air quality and ventilation in a building. Their design and installation play a crucial role in maintaining the integrity and performance of the HVAC system, directly influencing the indoor air environment.

Impact of HVAC Access Panels on Air Quality and Ventilation

- Facilitating Maintenance and Cleaning:

- Access panels provide entry points for regular cleaning and maintenance of HVAC components.

- Keeping these components clean is essential for preventing the circulation of dust, allergens, and other pollutants.

- Preventing Contaminant Entry:

- Well-designed and properly installed panels can prevent outdoor pollutants and moisture from entering the HVAC system.

- This is crucial in maintaining indoor air quality, especially in areas with high pollution levels.

- Ensuring Proper System Sealing:

- Panels need to be correctly sealed to prevent air leaks.

- Leaks can lead to inefficiencies in the HVAC system, impacting temperature control and air circulation.

Enhanced Ventilation Efficiency

- Optimizing Airflow:

- Access panels allow for the inspection and repair of ducts and vents, ensuring optimal airflow.

- Proper airflow is essential for effective ventilation, distributing clean air evenly throughout the building.

- Filter Maintenance Access:

- Panels provide easy access to filters, which are crucial for trapping contaminants.

- Regular filter maintenance helps maintain high air quality and efficient ventilation.

Compliance with Health Standards

- Meeting Air Quality Regulations:

- Regular access for system inspection and maintenance via panels helps in complying with air quality standards.

- Ensuring the HVAC system functions effectively is key to meeting health and safety regulations.

- Reducing Mold and Moisture Issues:

- By preventing moisture ingress, well-sealed panels help reduce the risk of mold growth in ducts.

- Mold and dampness can significantly degrade indoor air quality if not addressed

HVAC access panels facilitate essential maintenance and cleaning, help optimize airflow, and prevent contaminants from affecting the HVAC system. Proper sealing of these panels is critical in preventing air leaks, ensuring the system’s efficiency, and complying with health and safety standards.

19. Are there energy-efficient access panels for HVAC systems?

Yes, energy-efficient access panels for HVAC systems are available and increasingly popular, especially in the context of growing environmental awareness and the push for energy conservation. These panels are designed to enhance the overall efficiency of HVAC systems by reducing energy loss and improving insulation.

Features of Energy-Efficient Access Panels

- Improved Insulation:

- These panels often include enhanced insulation materials that reduce heat loss or gain, maintaining the desired temperature within the HVAC system.

- Better insulation helps in minimizing the energy required to heat or cool the air.

- Airtight Sealing:

- Energy-efficient panels are designed to seal tightly, preventing air leaks.

- Proper sealing is key in maintaining the efficiency of the HVAC system by avoiding unnecessary energy loss.

- Durable Materials:

- Constructed with materials that offer long-term durability and withstand environmental factors.

- Durability is important for maintaining the panel’s integrity and insulation properties over time.

Benefits of Using Energy-Efficient Panels

- Reduced Energy Consumption:

- By minimizing heat loss and air leaks, these panels help in reducing the overall energy consumption of the HVAC system.

- Lower energy consumption leads to cost savings and is beneficial for the environment.

- Enhanced System Performance:

- Improved efficiency of the HVAC system ensures consistent performance and better temperature regulation.

- This can lead to a more comfortable indoor environment.

- Long-Term Cost Savings:

- While the initial investment might be higher, energy-efficient panels can offer long-term savings through reduced energy bills.

- The reduced need for frequent maintenance or replacements can also contribute to cost savings.

Considerations for Selection

- Compatibility with Existing Systems: Ensure that the energy-efficient panels are compatible with your current HVAC system.

- Professional Installation: To maximize the benefits, it’s important that these panels are installed correctly by a professional.

- Compliance with Regulations: Energy-efficient panels can help in meeting building codes and regulations related to energy use and sustainability.

Energy-efficient access panels are an excellent choice for HVAC systems, offering improved insulation, airtight sealing, and durable materials that contribute to reduced energy consumption and enhanced system performance. While they may require a higher initial investment, the long-term benefits in terms of energy savings and environmental impact make them a worthwhile consideration for modern HVAC installations.

20. What are the noise considerations for access panels in HVAC systems?

Noise considerations are an important aspect of access panel design in HVAC systems. The panels play a role in either dampening or inadvertently amplifying the sound generated by the HVAC equipment.

Understanding Noise Considerations for HVAC Access Panels

- Material and Construction:

- The type of material used for the access panel can influence sound transmission. Dense materials like heavy-gauge steel can reduce noise more effectively.

- The thickness and density of the panel also contribute to its sound-dampening capabilities.

- Sealing and Insulation:

- Proper sealing of access panels is crucial to prevent sound leaks.

- Panels with insulation not only improve energy efficiency but can also absorb sound, reducing noise transmission.

- Location and Installation:

- The placement of access panels can affect how sound travels through building spaces.

- Correct installation is key to ensure that panels fit snugly and don’t vibrate or rattle, which can increase noise.

Solutions for Noise Reduction

- Soundproofing Materials:

- Using panels that incorporate soundproofing materials can significantly reduce noise levels.

- Materials like acoustic foam or sound-dampening layers can be integrated into the panel design.

- Acoustic Seals:

- Specialized acoustic seals around the panel edges can prevent sound leakage.

- These seals are designed to absorb sound vibrations, enhancing noise reduction.

- Vibration Dampening:

- Panels can be fitted with vibration dampeners to minimize the sound generated by the mechanical operation of the HVAC system.

- This is especially important for panels close to motors or fans.

Impact on Occupant Comfort and Compliance

- Enhanced Comfort: Reducing noise from HVAC systems contributes to a more comfortable and quieter indoor environment.

- Regulatory Compliance: In some cases, there are regulations regarding noise levels in buildings, especially in residential or commercial areas.

Noise considerations for HVAC access panels are vital for maintaining a pleasant and quiet indoor environment. The choice of materials, incorporation of soundproofing elements, proper sealing, and strategic installation all play a role in minimizing noise transmission. By addressing these factors, access panels can effectively contribute to a quieter operation of HVAC systems, enhancing occupant comfort and ensuring compliance with relevant noise regulations.

Need High-quality HVAC Grilles and Diffusers? Shoot us a message, and I’ll be happy to assist you in picking the right grilles or diffusers for your needs.