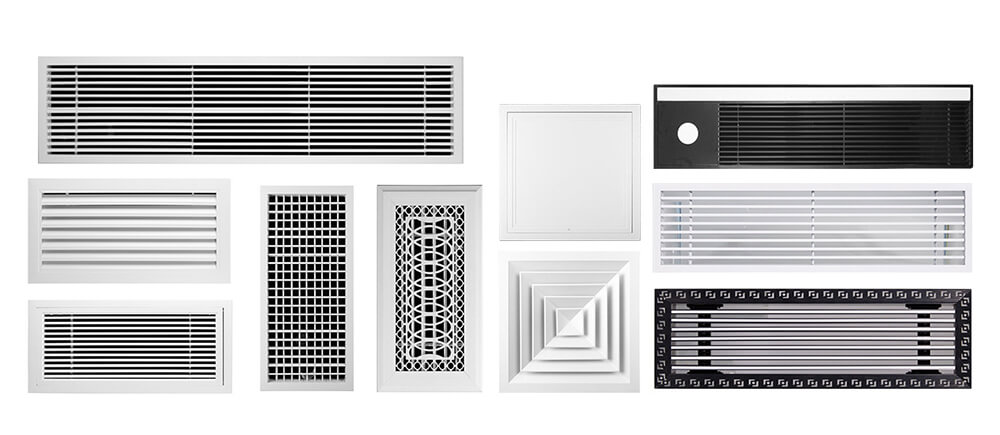

Central air conditioning systems commonly employ various materials for air diffusers. Currently, there are four main types: wood, aluminum alloy, ABS, and rigid PVC materials.

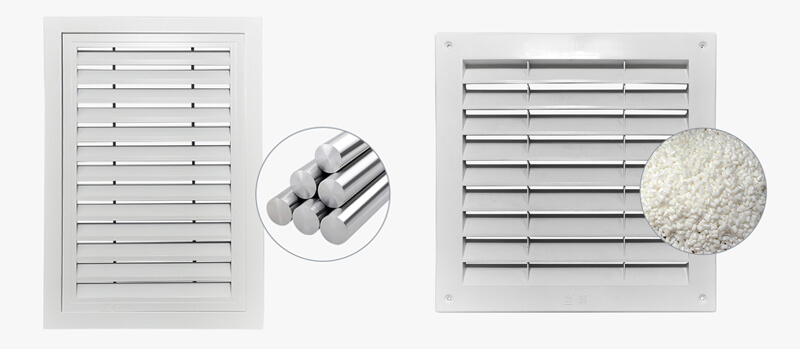

Aluminum Alloy Material

Aluminum alloy air diffusers are widely utilized among residential central air conditioning users.

- Condensation Issues: During summer cooling, if the air supply temperature is too low, inadequate insulation during installation, or insufficient airflow, condensation may occur at the air diffuser, sometimes leading to the formation of water droplets.

- Production Process Hazards: Aluminum alloy air diffusers undergo a series of production processes such as cutting, welding, painting, and baking. The hazards of paint are well recognized. Throughout the cooling and heating processes, air diffusers gradually release formaldehyde into the air, impacting health without one’s awareness.

PVC Material

PVC, or polyvinyl chloride, is a type of ethylene-based polymer, characterized by its non-crystalline nature. When used in residential central air conditioning, it exhibits a low propensity for condensation and boasts properties such as flammability resistance, high strength, weather resistance, and excellent geometric stability.

Properties of PVC Material

- Resistance to Oxidizing Agents: PVC demonstrates strong resistance to oxidizing agents, reducing agents, and strong acids.

- Density and Weight Comparison: Hard PVC material has a relatively high density (approximately 1.04, similar to ABS), making it about 1.5 times heavier than ABS or aluminum alloy for the same size area of the air diffuser.

- Yellowing and Discoloration: PVC air diffusers, when installed, may exhibit yellowing and severe discoloration over time, particularly noticeable in the winter months.

Drawbacks of PVC Material in Air Diffusers

- Temperature Sensitivity: PVC is not heat resistant, and during the winter when hot air is blown through, the material is prone to softening and deformation.

- Release of Harmful Gases: PVC air diffusers may undergo thermal decomposition during the heating process, releasing harmful gases such as hydrogen chloride and olefin gases, posing health risks to occupants.

- Comparison with ABS Material: A simple method to distinguish between ABS and PVC air diffuser materials is by burning: ABS produces a bright flame (with potential for self-sustaining combustion due to additives), while PVC exhibits flame retardancy and emits black smoke.

ABS Material (Plastic Steel Diffuser)

ABS material, also known as plastic steel diffuser, is composed of PS foam board and alloy material. It is a new type of material that substitutes plastic for wood. Primarily made from polyvinyl chloride (PVC) through special foaming processes, the product possesses various advantages:

- Moisture resistance

- Flame retardancy (self-extinguishing)

- Dimensional stability

- Non-toxicity

- Aesthetics

- Strong resistance to aging

Moreover, it exhibits excellent:

- Corrosion resistance

- Weather resistance

- Anti-corrosion

- Waterproofing

- Sound insulation

- Thermal insulation

- Insulation capabilities

The diffusers can be customized into various styles and sizes according to user requirements and decoration needs. However, the complex assembly process of PS materials contributes to its high price. Additionally, the inclusion of alloy materials renders the product relatively brittle, making the diffuser prone to cracking when installed with nail guns or self-tapping screws during winter.

Wooden Material

Wooden air diffusers seamlessly blend with specific interior decoration styles, enhancing overall aesthetics. However, during winter heating, significant temperature differentials between usage and non-usage of air conditioning can lead to deformation, cracking, and even mold and decay issues with wooden air diffusers.

Challenges in Winter Heating

- Deformation and Cracking: The fluctuation in temperatures during winter heating poses a risk of deformation and cracking for wooden air diffusers.

- Mold and Decay: Excessive moisture levels in the air can result in mold and decay, further compromising the integrity of wooden air diffusers.

Cost Considerations

- Production Costs: The production process of wooden air diffusers involves cutting and assembly, contributing to relatively high production costs.

- Price Comparisons: Despite their appeal, wooden air diffusers are relatively expensive due to the costs associated with production and maintenance.

Types and Advantages/Disadvantages of Air Diffuser Materials

1. Aluminum Alloy Air Diffusers

Aluminum alloy air diffusers are a common type of air diffuser that can be selected based on decorative style.

- Advantages:

- High cost-effectiveness with moderate pricing.

- Convenient customization of various shapes.

- Disadvantages:

- During summer cooling, condensation may occur on the surface due to excessively low air supply temperatures.

2. ABS Plastic Steel Air Diffusers

ABS plastic steel air diffusers are another common type that can be chosen according to decorative style.

- Advantages:

- An emerging resin material, less prone to deformation and condensation.

- Customizable shapes and available in various colors.

- Disadvantages:

- Slightly higher cost compared to other materials.

3. Wooden Air Diffusers

Wooden air diffusers are recommended only if specific decorative requirements are in place.

- Advantages:

- Aesthetically pleasing and tactile, suitable for high-end wooden decoration styles.

- Disadvantages:

- During winter heating, significant temperature differentials may cause deformation and cracking if used with air conditioning.

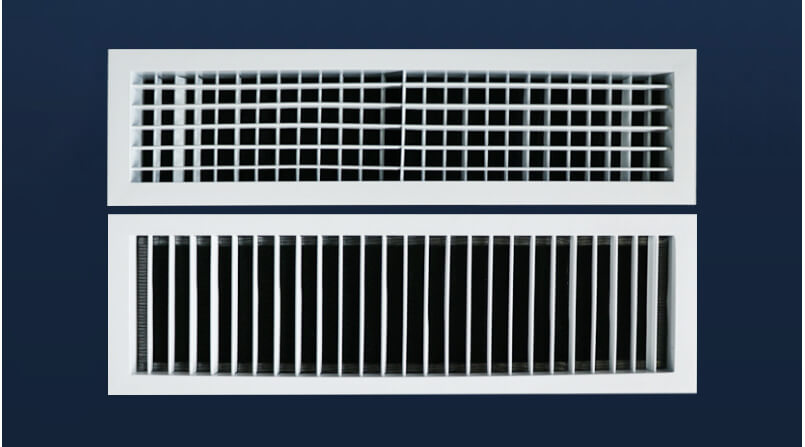

4. ABS Plastic Performance Testing

1) General Performance

Appearance: ABS appears as opaque ivory-colored granules, non-toxic, odorless, and with low water absorption. Its products can be produced in various colors and possess 90% high glossiness. ABS exhibits good adhesion with other materials and is easy for surface printing, coating, and plating treatment.

Combustibility: ABS has an oxygen index of 18.2, and classifies as a flammable polymer. When burned, it emits a yellow flame with black smoke, charred without dripping, and releases a distinctive cinnamon odor.

Comprehensive Performance: ABS is a resin with excellent comprehensive performance. It has high impact strength and surface hardness over a wide temperature range. Its heat deformation temperature is higher than PA and PVC, with good dimensional stability. ABS melt flow is better than PVC and PC but inferior to PE, PA, and PS, similar to POM and HIPS. ABS’s flow characteristics belong to non-Newtonian fluids, with melt viscosity related to processing temperature and shear rate, but more sensitive to shear rate.

2) Mechanical Properties

Impact Strength: ABS exhibits excellent mechanical properties with outstanding impact strength, suitable for use at very low temperatures. Even when ABS products are damaged, it tends to be tensile failure rather than impact failure.

Wear Resistance: ABS demonstrates excellent wear resistance, good dimensional stability, and oil resistance, suitable for bearings under medium loads and speeds.

Creep Resistance: ABS has a larger creep deformation compared to PSF and PC but smaller than PA and POM.

Bending and Compression Strength: ABS exhibits relatively poor bending and compression strength among plastics. The mechanical properties of ABS are significantly influenced by temperature.

3. Thermal Performance

Amorphous Polymer: ABS is an amorphous polymer with no distinct melting point, exhibiting high melt viscosity and poor flowability. It has moderate weather resistance but may discolor under UV exposure. The heat deformation temperature ranges from 70 to 107°C (around 85°C), which can increase by approximately 10°C through annealing. ABS demonstrates sensitivity to temperature and shear rate. It retains some toughness even at -40°C and can be used in the temperature range of -40°C to 85°C over the long term.

4. Electrical Performance

Insulation Properties: ABS exhibits good electrical insulation properties, minimally affected by temperature, humidity, and frequency, suitable for use in most environments.

5. Environmental Performance

Chemical Resistance: ABS is resistant to water, inorganic salts, alkalis, alcohols, and hydrocarbons, as well as various acids. However, it is soluble in ketones, aldehydes, and chlorinated hydrocarbons, and exposure to acetic acid, vegetable oils, etc., may cause stress cracking.

Performance Testing: Performance testing involves automated tools simulating various normal, peak, and abnormal load conditions to evaluate system performance metrics.

If you want to know more, please click below:

- Grilles, Registers & Diffusers – The Ultimate Guide

- HVAC Linear Slot Diffusers – The Ultimate Guide

- HVAC Egg Crate Diffuser – The Ultimate Guide

- HVAC Jet Nozzle Diffuser – The Ultimate Guide

- HVAC Linear Bar Grilles – The Ultimate Guide

- HVAC Air Swirl Diffusers – The Ultimate Guide

- HVAC Round Ceiling Diffusers – The Ultimate Guide

- Round Ceiling Diffusers – The Ultimate Guide

- Exhaust Air Louver – The Ultimate Guide

- HVAC Registers – The Ultimate Guide